Troubleshooting

309584H

9

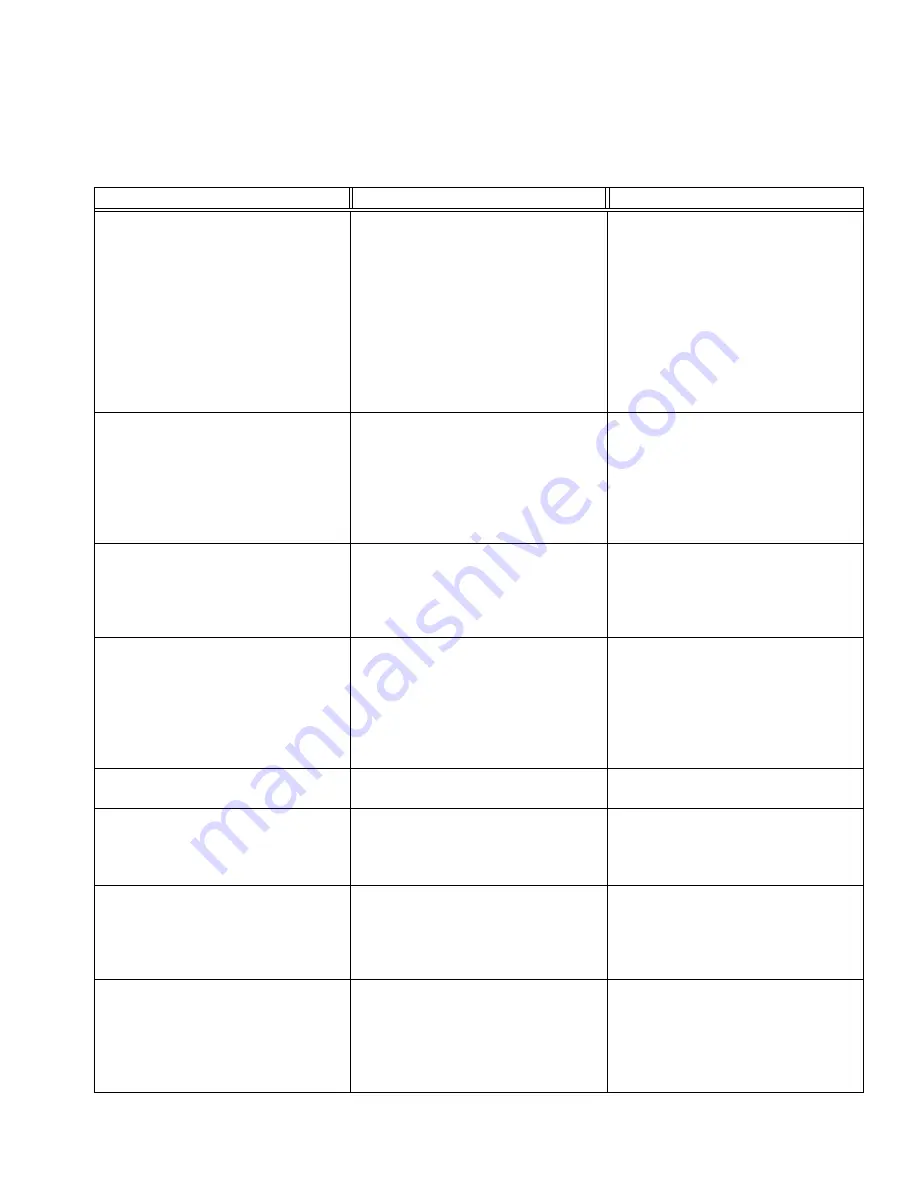

Troubleshooting

Problem

Cause

Solution

Material will not flow from hopper

•

Material too thick.

•

Not enough air

•

Gun adjustment set too low

•

Nozzle too small

•

Gun is plugged

•

Not enough material in hopper.

•

Thin material

•

Open gun air valve more

•

Increase trigger travel

•

Increase nozzle size

•

Clean gun

•

Add material

Pattern too fine.

•

Material too thin

•

Air pressure too high

•

Gun needle travel too low

•

Nozzle too small.

•

Thicken

•

Close gun air valve partially

•

Increase

•

Replace nozzle with larger size

Pattern too course.

•

Material too thick.

•

Air pressure too low.

•

Nozzle to large.

•

Thin material

•

Open gun air valve more

•

Replace nozzle with smaller size

Gun will not shut off

•

Worn nozzle or needle

•

Nozzle not on all the way

•

Debris in needle passage

•

Relieve Pressure

, page 3.

Replace worn parts.

•

Tighten completely.

•

Relieve Pressure

, page 3.

Clean.

Fluid leaking at Flow Adjustment Nut Damaged seal.

Relieve Pressure

, page 3. Replace

seal.

Fluid leaking out of either plug

•

Missing or damaged o-rings

•

Gun damaged

•

Relieve Pressure

, page 3.

Replace o-ring

•

Replace gun

Needle adjustment won’t adjust

•

Dirty threads

•

Nozzle not on gun

•

Needle triggered

•

Clean threads

•

Put nozzle on gun

•

Adjust when trigger not pulled

Material leaking out around gun/hop-

per connection

•

Clamp not tight

•

Damaged gun/hopper

•

Debris between gun/hopper

•

Tighten

•

Check for damage. Replace.

•

Remove hopper from gun. Clean.

Replace hopper.

Summary of Contents for 245924 A Series

Page 11: ...Notes 309584H 11 Notes...