Maintenance

4

313347C

Clearing RAC Tip Clogs (257096)

1.

Relieve pressure. Set trigger lock (A).

2.

Rotate tip (B) 180°. Unlock trigger lock (A). Trigger

gun into pail or onto ground to remove clog.

3.

Set trigger lock (A). Rotate tip (B) 180° back to spray

position.

Maintenance

Before performing any maintenance on gun, read all

warnings on front cover of this manual and relieve

pressure.

Daily Maintenance

Flush gun after each work shift and store in a dry location.

Do not immerse the gun or any parts in water or cleaning

solvents.

•

Do not point gun up while cleaning it.

•

Do not wipe gun with cloth soaked in solvent; wring

out excess.

•

Solvent left in gun air passages could result in a poor

quality paint finish. Do not use any cleaning method

that may allow solvent into gun air passages.

Flushing and Cleaning

• Flush gun before changing colors, before storing and before

repairing gun.

• Flush at lowest possible pressure. Check connectors for

leaks and tighten as necessary.

• Flush with fluid compatible with fluid being dispensed and

equipment wetted parts.

1.

Relieve pressure. Unplug sprayer.

2.

Remove tip (28) and guard (29).

3.

Remove sprayer siphon tube set from paint and place

in flushing fluid. See Cleanup instructions in sprayer

operation manual 313316.

4.

Plug sprayer in outlet. Set sprayer function selection

switch to AIRLESS or ON.

5.

Increase pressure slowly. Point gun down into

grounded metal container. Pull gun trigger and flush

gun with solvent until all traces of fluid are removed

from gun passages.

6.

Turn sprayer function selection switch to OFF.

7.

Relieve pressure, page 2.

8.

Disconnect fluid supply hose from gun.

9.

If it is necessary to remove diffuser (5) to clean, follow

Needle Replacement Removal procedure, steps 1

through 6.

10. Dip soft-bristle brush into a compatible solvent.

Do

not use a wire brush

.

11. Point gun down, clean front of gun with soft-bristle

brush and solvent.

12. Scrub tip (28) and guard (29) with soft-bristle brush.

Clean air cap holes with a toothpick to avoid

damaging critical surfaces. Blow air through spray tip

(28) to ensure orifice is clean.

13. If diffuser (5) was removed, trigger gun while you

reinstall diffuser. Torque to 26-32 ft-lb (36-40 N•m).

When properly tightened, flange bottoms out on gun.

14. Install air cap manifold; follow Needle Replacement

Installation procedure, steps 9 - 13.

15. Install tip (28) and guard (29) on gun, page 2.

16. Wipe off outside of gun with soft cloth dampened in

solvent,

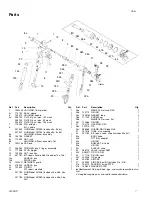

Cleaning/Replacing Filter (6)

1.

Relieve pressure. Set trigger lock (11a).

2.

Disconnect fluid hose from gun at swivel (5).

3.

Disconnect bracket (36) from retainer (16) and swivel

out of way.

4.

Place a wrench on flats below handle and loosen

from gun.

5.

Unscrew handle (14) from gun (1).

6.

Remove filter (6) through top of handle (14).

7.

Clean filter (6). Use a soft brush to loosen and

remove excess debris.

8.

Insert clean filter (6) into handle (14).

9.

Reattach handle (14) to gun (1). Tighten securely.

10. Place a wrench on flats below handle and tighten

securely.

11. Connect bracket (36) to retainer (16).

WARNING