Flushing

Flushing

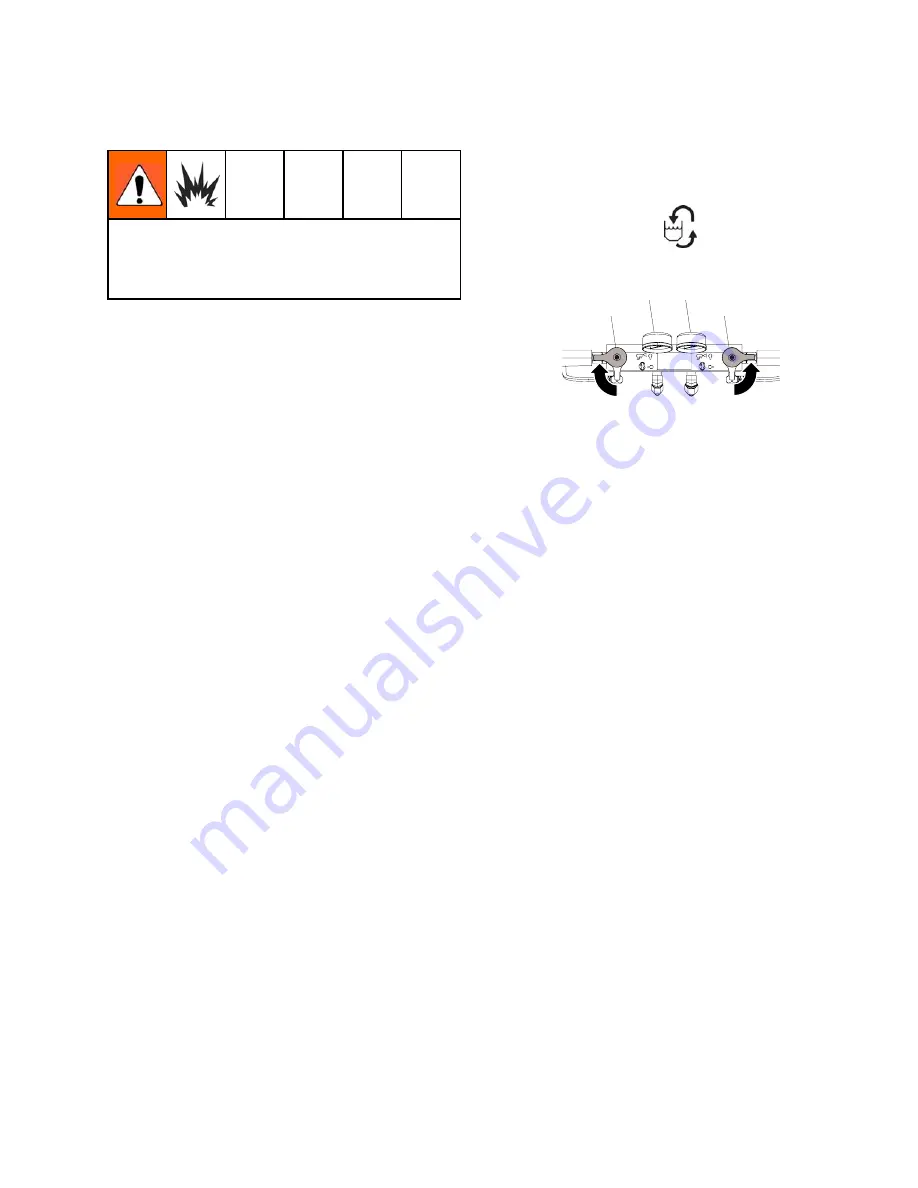

To prevent fire and explosion, flush equipment only

in a well-ventilated area. Do not spray flammable

fluids. Do not turn on heaters while flushing with

flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All wetted parts are compatible with common

solvents. Use only moisture-free solvents.

• To flush feed hoses, pumps, and heaters

separately from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION

. Flush through bleed

lines (N).

SA

SB

GA

GB

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system filled with a moisture-free

plasticizer or oil. Do not use water. Never

leave the system dry. See Important Two-

Component Material Information, page 7.

3A1705E

65

Summary of Contents for 259079

Page 34: ...Setup A5 A1 A2 AS AN A3 AT A3 A4 A2 A6 A4 34 3A1705E...

Page 45: ...Advanced Display Module ADM Operation Setup Screens Navigation Diagram Figure 35 3A1705E 45...

Page 49: ...Advanced Display Module ADM Operation Run Screens Navigation Diagram Figure 36 3A1705E 49...

Page 93: ...Dimensions Dimensions Top View Figure 43 Side View Figure 44 3A1705E 93...

Page 95: ...Dimensions Pallet Mounting Dimensions Figure 48 3A1705E 95...

Page 97: ...Notes Notes 3A1705E 97...