Setup

Install Wall (optional)

Install a wall between the proportioner and generator

to:

•

Temperature condition the trailer space where

chemical is stored. Check with chemical

manufacturer for chemical storage temperatures.

•

Reduce noise for the operator while the Reactor

is running.

The supplied fuel lines and battery cable may need

to be replaced if a wall is installed between the

proportioner and generator. Purchase the Fuel Line

and Battery Cable Extension Kit 24K333.

1.

If necessary drain coolant from system. See

Drain Coolant, page 69. Coolant lines do not

need to be disconnected to install a wall.

Note

Battery must be connected to starter to

drain coolant from system.

2.

Remove screws and battery bracket from the

pallet.

Remove Battery Bracket and Fuel Tank

Figure 26

3.

Remove fuel tank from the pallet.

a.

Remove the mounting screws, supports, and

spacers.

b.

Disconnect inlet and outlet fuel lines from the

fuel tank.

c.

Use two people to lift fuel tank off of the pallet

and place where the fuel fill spout is easily

accessible.

Note

Do not mount fuel tank in front of

the generator air intake or where it

will limit opening and access to the

electrical enclosure (DB).

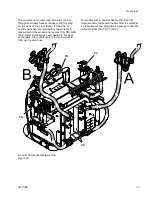

4.

Install wall (IW) where the fuel tank was located.

Ensure there is at least 1.25 in. (31.75 mm)

between the wall, exhaust muffler, and MCM.

Note

To prevent an air pocket from forming

inside the coolant lines between the

proportioner and generator, ensure

there is a constant rise in elevation if

the coolant lines are adjusted. Failure

to have a constant rise in elevation will

reduce heating efficiency.

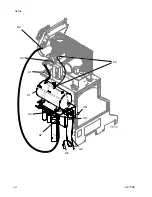

5.

Reconnect inlet and outlet fuel lines.

6.

Install spacers, supports, and screws through

the fuel tank and tighten to the floor. Torque to

40 ft-lbs (54 N•m).

7.

Place battery bracket over fuel tank or near the

Reactor. Remove existing battery cables from

engine and replace with the cables provided from

the fuel line and battery cable extension kit.

8.

Install mounting bolts through battery bracket and

tighten to the floor. Torque to 40 ft-lbs (54 N•m).

Note

Pads under the battery bracket help

stabilize the fuel tank during operation.

36

3A1705E

Summary of Contents for 259079

Page 34: ...Setup A5 A1 A2 AS AN A3 AT A3 A4 A2 A6 A4 34 3A1705E...

Page 45: ...Advanced Display Module ADM Operation Setup Screens Navigation Diagram Figure 35 3A1705E 45...

Page 49: ...Advanced Display Module ADM Operation Run Screens Navigation Diagram Figure 36 3A1705E 49...

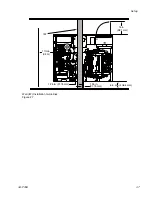

Page 93: ...Dimensions Dimensions Top View Figure 43 Side View Figure 44 3A1705E 93...

Page 95: ...Dimensions Pallet Mounting Dimensions Figure 48 3A1705E 95...

Page 97: ...Notes Notes 3A1705E 97...