Shutdown

Shutdown

NOTICE

Proper system setup, startup, and shutdown

procedures are critical to electrical equipment

reliability. The following procedures ensure steady

voltage. Failure to follow these procedures will

cause voltage fluctuations that can damage

electrical equipment and void the warranty.

1. Press

to stop the pumps.

2. Turn off heat zones.

3. Relieve pressure. See

Pressure Relief Procedure, page 64.

4. Press

to park the Component A Pump.

5. Press

to deactivate the system.

6. Turn off the air compressor, air dryer, and

breathing air.

7. Close the main air shutoff valve.

8. Turn main power switch OFF.

To prevent electric shock do not remove any

shrouds or open the electrical enclosure door.

240 V is still present in the system until the

engine has stopped.

9. Allow engine dwell time.

NOTICE

Allow engine dwell time, per manufacturer

recommendations, prior to shutdown. Dwell

time will help engine cool down after running at

operating temperature for any period of time.

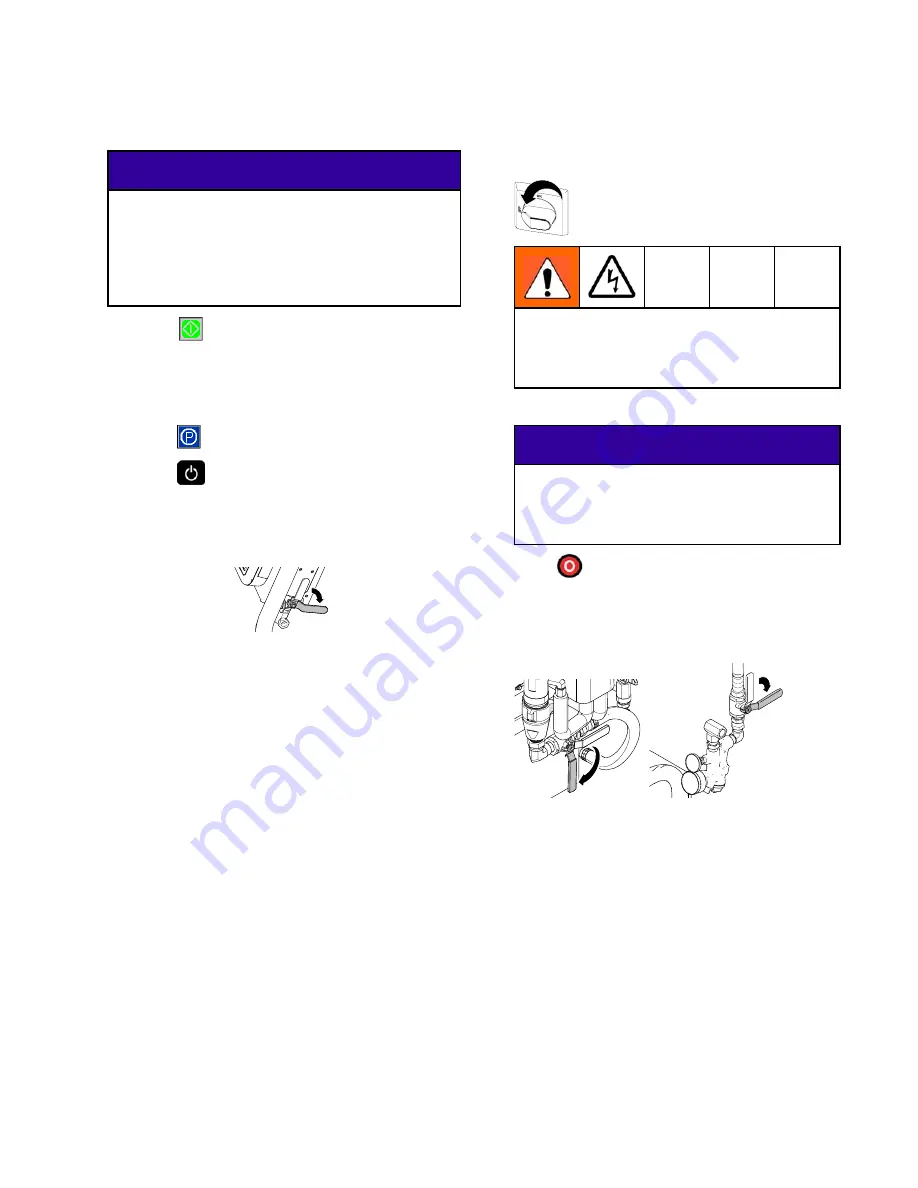

10. Press

on the engine control module.

11. Open air compressor bleed valve to relieve

pressure and remove water from tank.

12. Close all fluid supply valves.

3A1705E

63

Summary of Contents for 259079

Page 34: ...Setup A5 A1 A2 AS AN A3 AT A3 A4 A2 A6 A4 34 3A1705E...

Page 45: ...Advanced Display Module ADM Operation Setup Screens Navigation Diagram Figure 35 3A1705E 45...

Page 49: ...Advanced Display Module ADM Operation Run Screens Navigation Diagram Figure 36 3A1705E 49...

Page 93: ...Dimensions Dimensions Top View Figure 43 Side View Figure 44 3A1705E 93...

Page 95: ...Dimensions Pallet Mounting Dimensions Figure 48 3A1705E 95...

Page 97: ...Notes Notes 3A1705E 97...