Maintenance

Flush Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

Isocyanate can crystallize from moisture

contamination or from freezing. If the chemicals used

are clean and proper storage, transfer, and operating

procedures are followed, there should be minimal

contamination of the A-side screen.

Note

Clean the A-side screen only during

daily startup. This minimizes moisture

contamination by immediately flushing

out any isocyanate residue at the start of

dispensing operations.

1.

Close the fluid inlet valve at the pump inlet and

shut off the appropriate feed pump. This prevents

material from being pumped while cleaning the

screen.

2.

Place a container under the strainer base to catch

drain off when removing the strainer plug (C).

3.

Remove the screen (A) from the strainer

manifold. Thoroughly flush the screen with

compatible solvent and shake it dry. Inspect the

screen. No more than 25% of the mesh should

be restricted. If more than 25% of the mesh is

blocked, replace the screen. Inspect the gasket

(B) and replace as required.

4.

Ensure the pipe plug (D) is screwed into the

strainer plug (C). Install the strainer plug with the

screen (A) and gasket (B) in place and tighten.

Do not overtighten. Let the gasket make the seal.

5.

Open the fluid inlet valve, ensure that there are

no leaks, and wipe the equipment clean. Proceed

with operation.

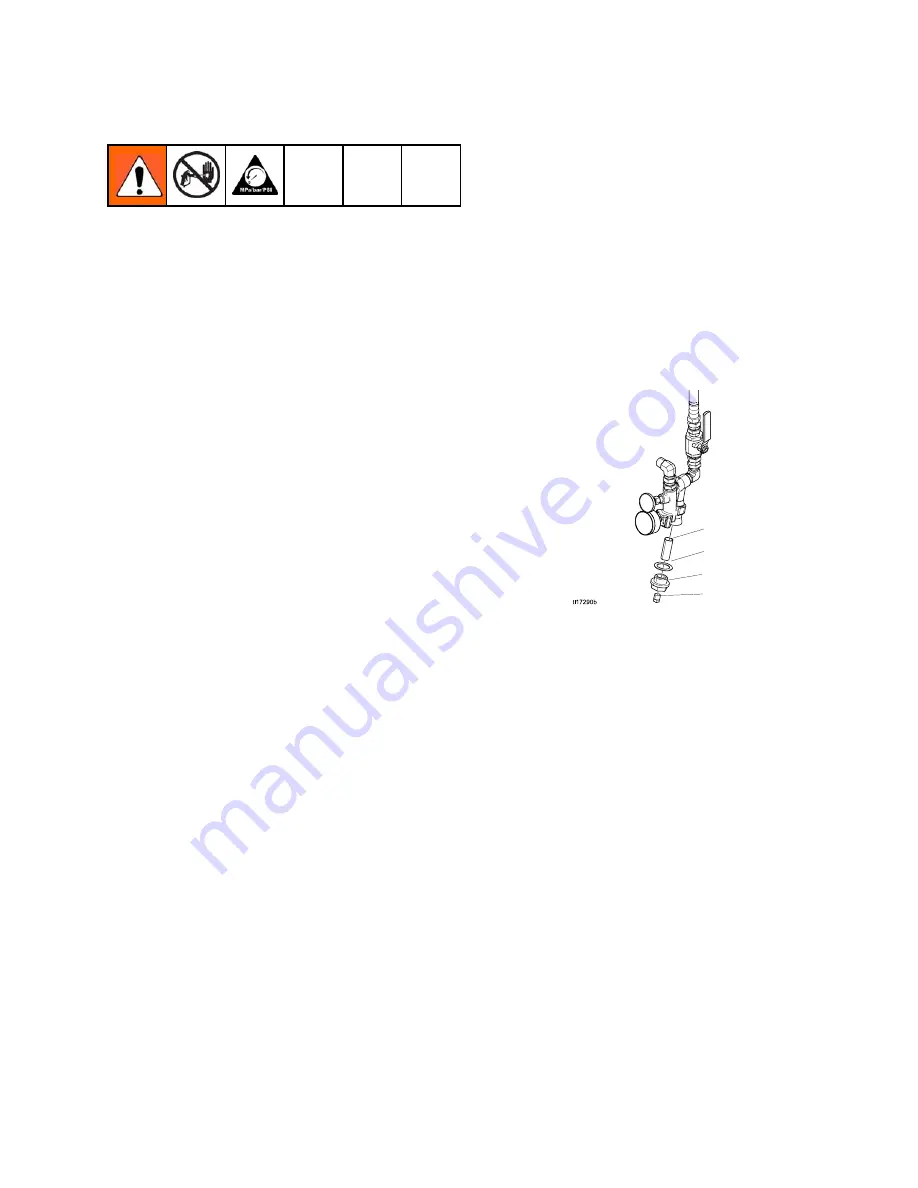

A

B

C

D

Figure 37

3A1705E

67

Summary of Contents for 259079

Page 34: ...Setup A5 A1 A2 AS AN A3 AT A3 A4 A2 A6 A4 34 3A1705E...

Page 45: ...Advanced Display Module ADM Operation Setup Screens Navigation Diagram Figure 35 3A1705E 45...

Page 49: ...Advanced Display Module ADM Operation Run Screens Navigation Diagram Figure 36 3A1705E 49...

Page 93: ...Dimensions Dimensions Top View Figure 43 Side View Figure 44 3A1705E 93...

Page 95: ...Dimensions Pallet Mounting Dimensions Figure 48 3A1705E 95...

Page 97: ...Notes Notes 3A1705E 97...