LL200 Compressor Installation

10

332230P

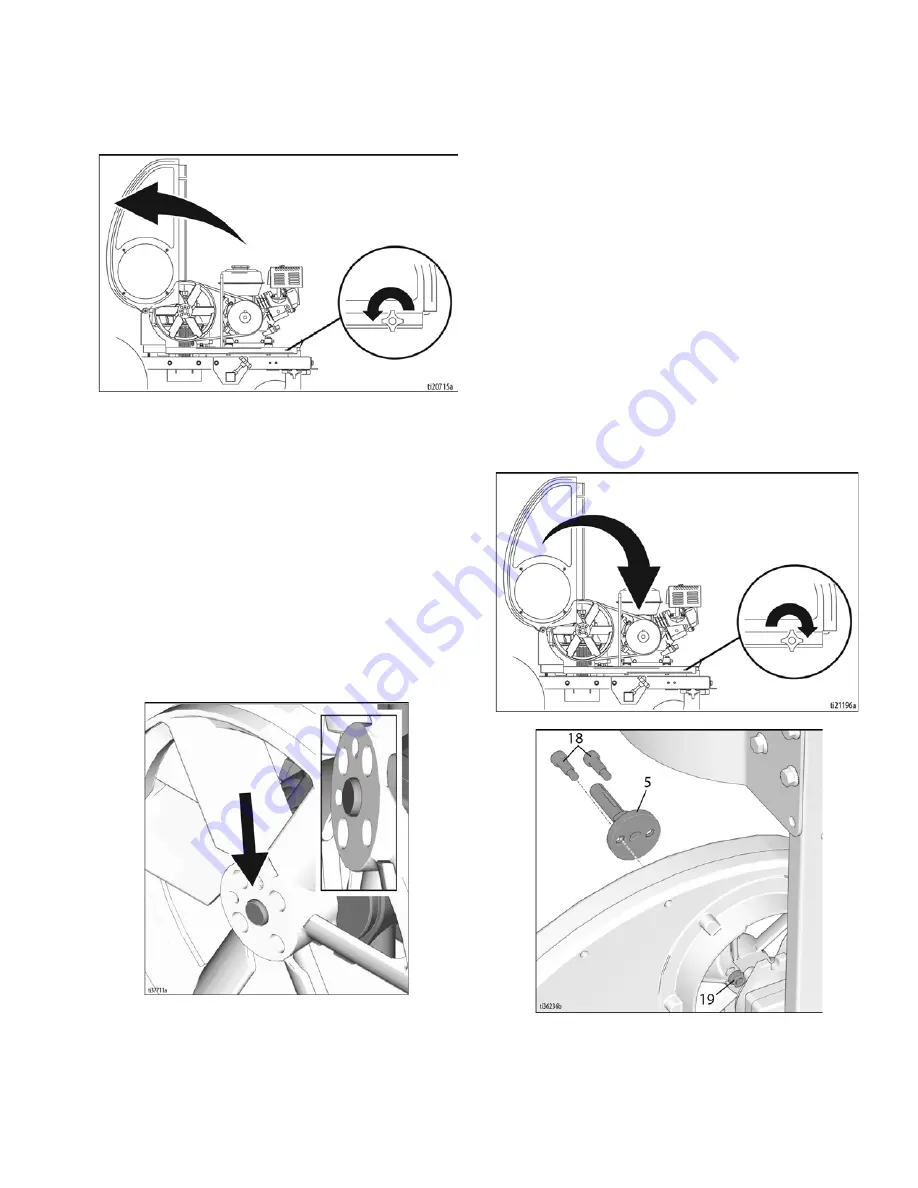

7. Locate belt shroud. Loosen knob and rotate shroud.

8. Using a 1/4 in. Allen wrench, remove shoulder bolts

and serrated nuts securing existing coupler plate.

NOTE:

Do

not

use ball end Allen wrenches, as they

may break and become stuck in the screws.

9. Loosen set screws on pulley. Lift engine to provide

slack for the belt and remove old pulley (X).

10. File any rough spots on the pump shaft key.

11. Slide new pulley on to the pump shaft. Pump shaft

must

extend 0.125-0.225 in. (3.175-5.73 mm)

beyond the face of the pulley. The pump shaft is the

pilot for the coupler adapter.

12. Torque pulley set screws to 58-62 in-lb (6.6-7 N•m).

13. Install belt on pulley. Refer to

Ground Drive Belt

Replacement

in your striper repair manual for

additional instructions and belt tension

recommendations.

NOTE:

Before performing step 14, securing nuts to back

of pulley with piece of duct tape will assist with

installation.

14. Put belt shroud down, install shaft coupler (5) onto

pulley with two shoulder screws (18) and serrated

nuts (19). Position slot on back of pulley up and

move serrated nut with finger to accept shoulder

bolt threads. Tighten using shoulder bolt by hand

until the teeth on the serrated nut catch the

aluminum on the fan. Using a 1/4 in. Allen wrench,

torque to 16-18 ft-lb (21-24 N•m).