LL250 Compressor Installation

22

332230P

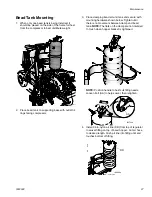

17. Place drop of medium strength thread locker on the

threads of each set screw. Using a 2.5 mm and a

4.0 mm Allen wrench, screw the set screws into the

shaft collar far enough so that the shaft collar can

slide on the compressor shaft sleeve. Rotate the

shaft collar so the pin faces up. Align the shaft collar

pin with the compressor shaft keyway as shown.

Slide the shaft collar onto the compressor shaft, pin

first.

18. Using a long screw driver, slowly rotate the fan

pulley. With the keyway of the coupler mounting

plate facing up, place the key into the shaft keyway

with the key slid to the end of the shaft keyway (as

shown). A light tap with a rubber mallet may be

needed to ensure the key seats completely.

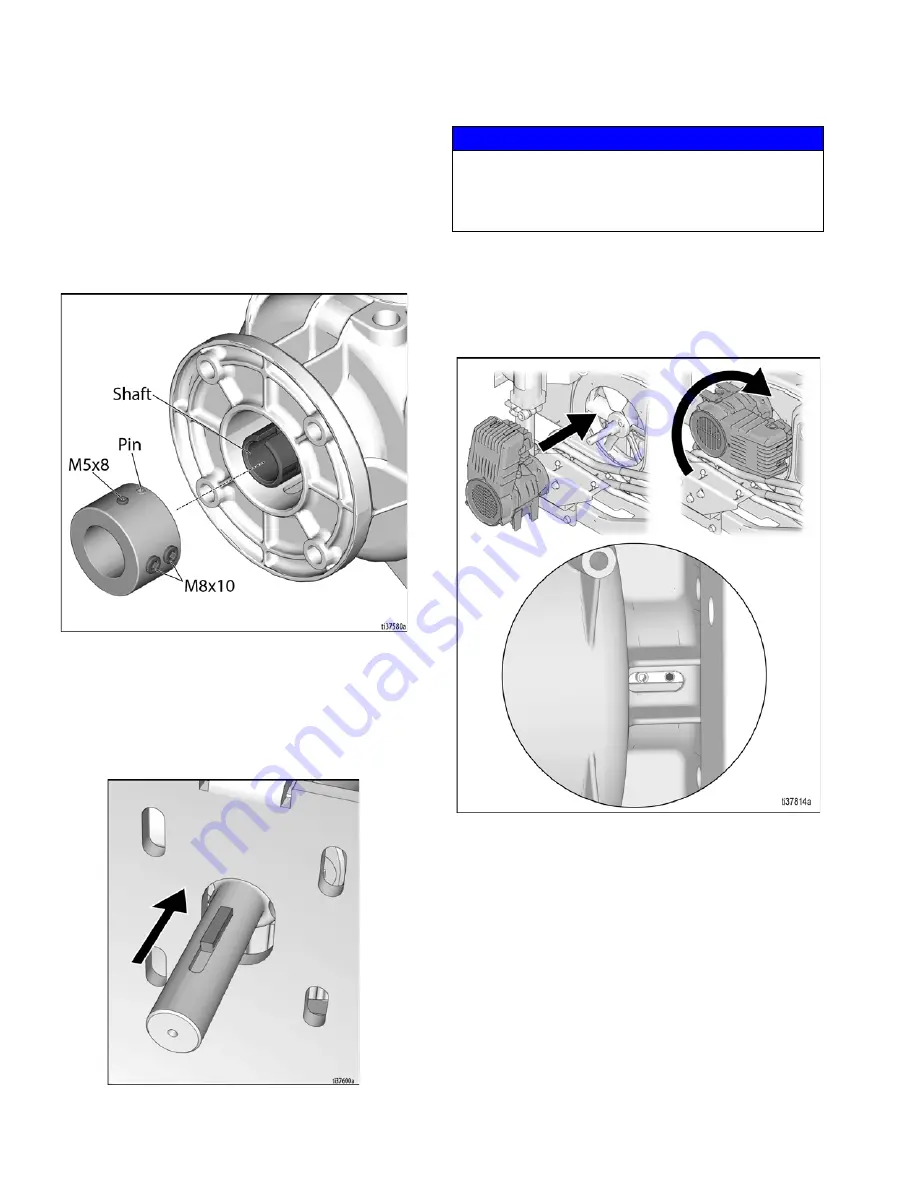

19. Slide the compressor onto the coupler mounting

plate until the face of the compressor is flush with

the compressor bracket. Rotate the compressor 90

degrees clockwise so that the set screw access is

accessible.

NOTICE

Performing steps 19 through 23 out of order, or

incorrectly, may cause excessive side loading on the

compressor crankshaft and could cause a premature

failure of the compressor.