Startup

12

310820H

9

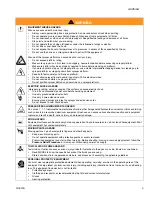

Move gun to paint pail and

trigger for 20 seconds. Set

gun safety ON.

10

Screw tip assembly onto

gun. Tighten. For gun

assembly instructions, see

gun manual, 309639.

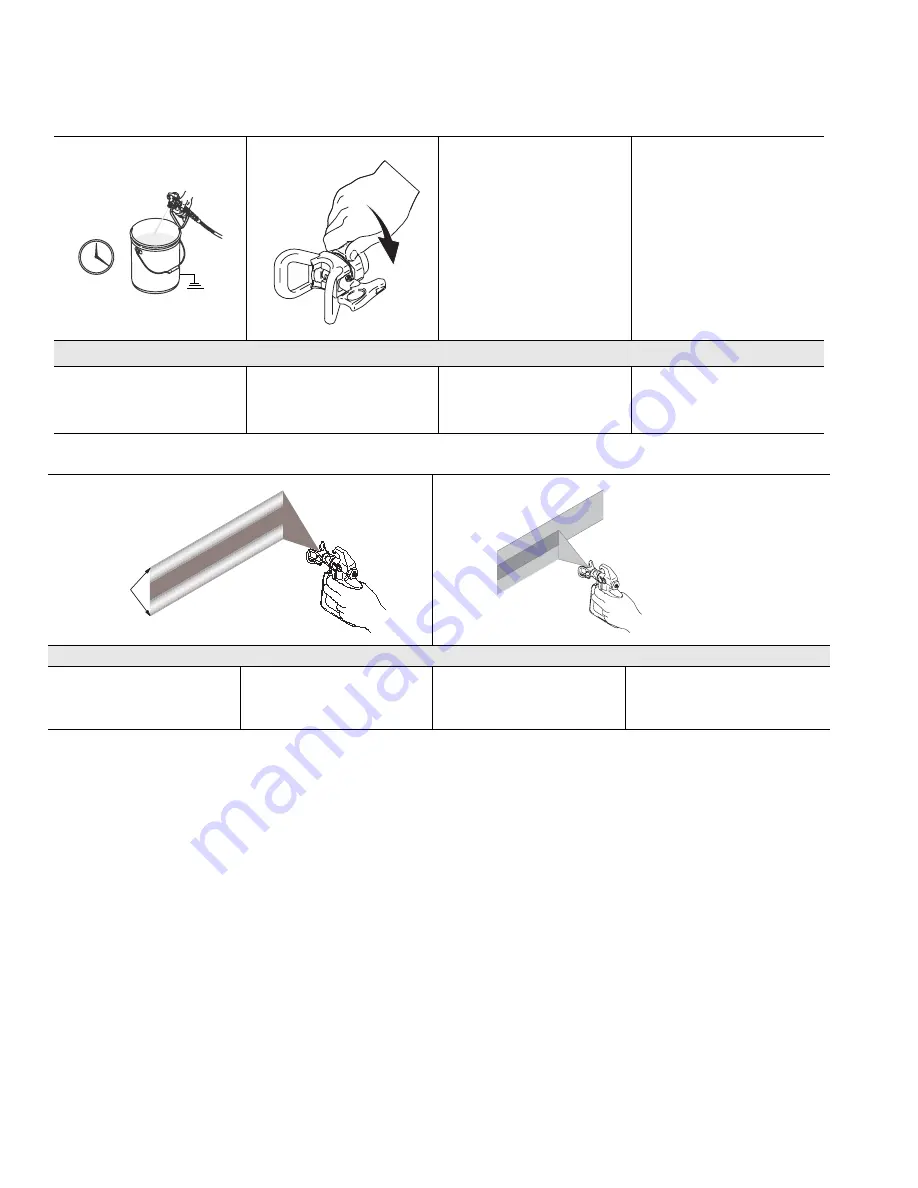

1

Spray test pattern. Adjust

pressure to eliminate heavy

edges.

2

Use smaller tip size if

pressure adjustment cannot

eliminate heavy edges.

3

Hold gun perpendicular,

10-12 in. from surface. Spray

back and forth; overlap by

50%.

4

Trigger gun before moving.

Release before stopping. For

additional spraying information,

see gun manual 309639.

20 seconds

ti2710a

heavy

edges

ti2757a

ti2758a