12

307–452

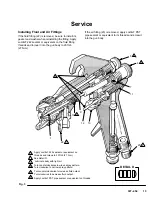

Service

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Relieve the pressure before you check or service any

system equipment.

NOTE: The fluid needle spring (7) and the air valve

spring (11) are not interchangeable. The air valve

spring (11) is slightly larger in diameter and will not fit

into the fluid valve cavity. See Fig. 3.

Air Valve Service

1.

If there is air leakage at the air valve needle (12),

remove the trigger and unscrew the air valve as-

sembly. See Fig. 3.

2.

Clean and inspect the needle (12), spring (11) and

air valve (13) for wear or damage. Replace if

needed.

3.

Apply a few drops of light-weight machine oil to the

air valve needle (12) and reassemble the air valve.

Fluid Packing Replacement

1.

If leakage occurs at the fluid needle packing nut

(9), tighten the nut. If leakage does not stop, re-

move the fluid adjusting valve knob (6), spring (7)

and needle (1). See Fig. 3.

2.

Unscrew the packing nut (9) and remove the old

packings (10). A small hooked tool can be used to

remove packings from the cavity. Clean and in-

spect all the parts for wear or damage, replacing

parts as needed.

3.

Lubricate the new packings and the needle with

lightweight oil and insert the packings into the cav-

ity in the order shown in Fig. 3, Detail D.

4.

Install the needle (1). Slide the packing nut (9) onto

the needle before inserting the needle into the

packing cavity. Then install the spring (7) and the

fluid adjusting knob (6) into the gun body.

5.

Turn the fluid adjusting knob (6) in until it bottoms

out, then back it out six full turns for proper spring

adjustment.

6.

With the trigger released, screw the packing nut (9)

in until the packings are fully compressed, then

back it off until the needle moves freely when the

gun is triggered.

NOTE: For the best fluid packing life, lubricate the gun

daily as explained in Maintenance.