8

307–452

Operation

Pressure Relief Procedure

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying acci-

dentally. To reduce the risk of an injury from acci-

dental spray from the gun, splashing fluid, or mov-

ing parts, follow the Pressure Relief Procedure

whenever you:

D

are instructed to relieve the pressure,

D

stop spraying,

D

check or service any of the system equipment,

D

or install or clean the spray nozzles.

WARNING

1.

Turn off the air and fluid supply to the gun.

2.

Trigger the gun into a grounded metal waste con-

tainer to relieve system pressures.

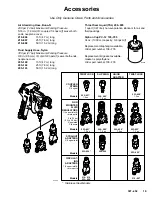

Filter the Fluid

Strain or filter the fluid to remove coarse particles and

sediment, then check the viscosity of the fluid. Install

the proper needle/nozzle set and air cap combination

selected from the charts on page 5.

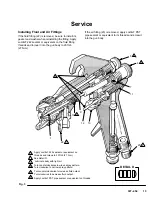

Adjusting the Spray Pattern (See Fig. 3)

The desired pattern, volume of fluid output and degree

of atomization can easily be obtained by regulating the

fan adjustment valve (5) and the fluid adjustment

knob (6).

Adjust the Pattern Size

Turn the fan adjustment valve (5) out (counterclock-

wise) to make the spray pattern wider.

Adjust the Fluid Output Volume for Pressure Feed

Turn the fluid adjustment knob (6) out all the way

(counterclockwise). Then adjust the air pressure at the

pressure feed tank until the desired fluid flow is ob-

tained. For the final adjustment, turn the fluid adjust-

ment knob in (clockwise) to reduce the volume of fluid

output until the desired results are obtained.

Adjust the Fluid Output Volume for Siphon or

Gravity Feed

Turn the fluid adjustment knob (6) in (clockwise) to

reduce the volume of fluid output, and turn it out (coun-

terclockwise) to increase the fluid output.

NOTE: If the fluid adjustment knob is turned in all the

way, the gun will emit only air.

Test the Spray Pattern

Hold the gun about 10 in. (254 mm) away from the sur-

face of the test piece. Adjust the air pressure to the

gun until proper atomization is achieved. Use the low-

est possible air pressure to obtain the desired results.

NOTE: The air adjustment valve (17) can also be used

to regulate air at the gun.

Continuous Spraying

Leave the fan and fluid adjustment valves in the full

open positions. This provides maximum fluid flow and

prevents premature wear on the fluid nozzle. Use sep-

arate regulators to control the air and fluid flow to the

gun.

Short-term Operations

The pattern size and fluid output volume may be re-

duced by turning in the fan and fluid adjustment valves.

Spray Pattern Direction

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure at left.

The

direction of the spray pattern is determined by the

position of the air cap (3). The horns of the air cap

should be the opposite direction (horizontal or vertical)

of the desired direction of the spray pattern. To change

the spray pattern direction, first relieve the pressure.

Then loosen and turn the air cap to the desired position

and hand tighten the air cap securely.

Proper pattern adjustment will give a spray pattern

shaped like this:

Vertical Pattern

Horizontal Pattern

See the Troubleshooting Chart for the cause and so-

lution of improper spray patterns.