9

307–452

Maintenance

CAUTION

To avoid contaminating the fluid being sprayed, be

sure that the solvents used are compatible with the

fluid being sprayed.

To avoid getting solvent in the gun air passages,

never immerse the gun in solvent.

CAUTION

Methylene Chloride with formic or propionic acid is

not recommended as a flushing or cleaning solvent

with this gun or any other device with nylon or alu-

minum components, as it can damage these parts.

Cleaning

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

1.

To clean the gun, flush it with a compatible solvent

until all traces of paint are removed from the gun

passages.

2.

Relieve the pressure.

3.

Wipe the outside of the gun clean with a solvent

dampened cloth.

4.

If the air cap and fluid nozzle need cleaning, re-

lieve the pressure, and remove the air cap (3)

from the gun. Remove the fluid nozzle with the

special nozzle wrench (21), supplied. Soak the

fluid nozzle in solvent and wipe it with a clean

cloth. Soak the air cap in solvent and scrub it with

a fine bristled brush (20). To clean the holes in the

air cap, use a toothpick or other soft implement to

avoid damaging critical surfaces.

CAUTION

Never use metal instruments to clean holes in the

air cap and nozzle. Metal instruments can damage

the holes in the air cap and fluid nozzle, resulting in

distortion of the spray pattern.

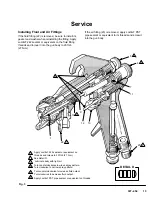

Lubricating

Lubricate the gun daily with light oil at the points

marked

in Fig. 3. Periodically lubricate the fluid

needle spring (7) with lightweight grease or petroleum

jelly.