Setup

3A4442F

11

Setup

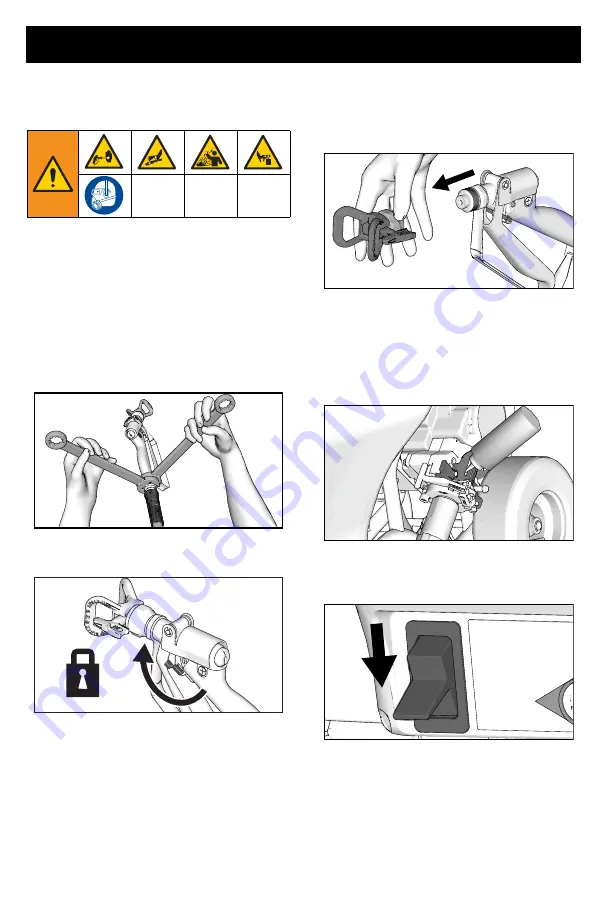

When unpacking sprayer for the first time or

after long term storage perform setup

procedure. When first setup is performed

remove shipping plug from fluid outlet.

1.

Connect Graco airless hose to fluid

outlet. Use wrenches to tighten securely.

2.

Connect whip hose (if applicable) and

gun to other end of hose. Apply thread

sealant and tighten securely.

3.

Engage trigger lock.

4.

Remove tip guard.

5.

A hopper strainer is used to prevent

debris from entering the pump.

6.

Fill throat packing nut with Graco TSL to

prevent premature packing wear. Do this

each time you spray.

7.

Turn ON/OFF switch to the

OFF

position.

8.

Plug power supply cord into a properly

grounded electrical outlet.

ti29973a

ti29974b

ti29975a

ti29976a

ti29972a