Maintenance

26

309550ZAP

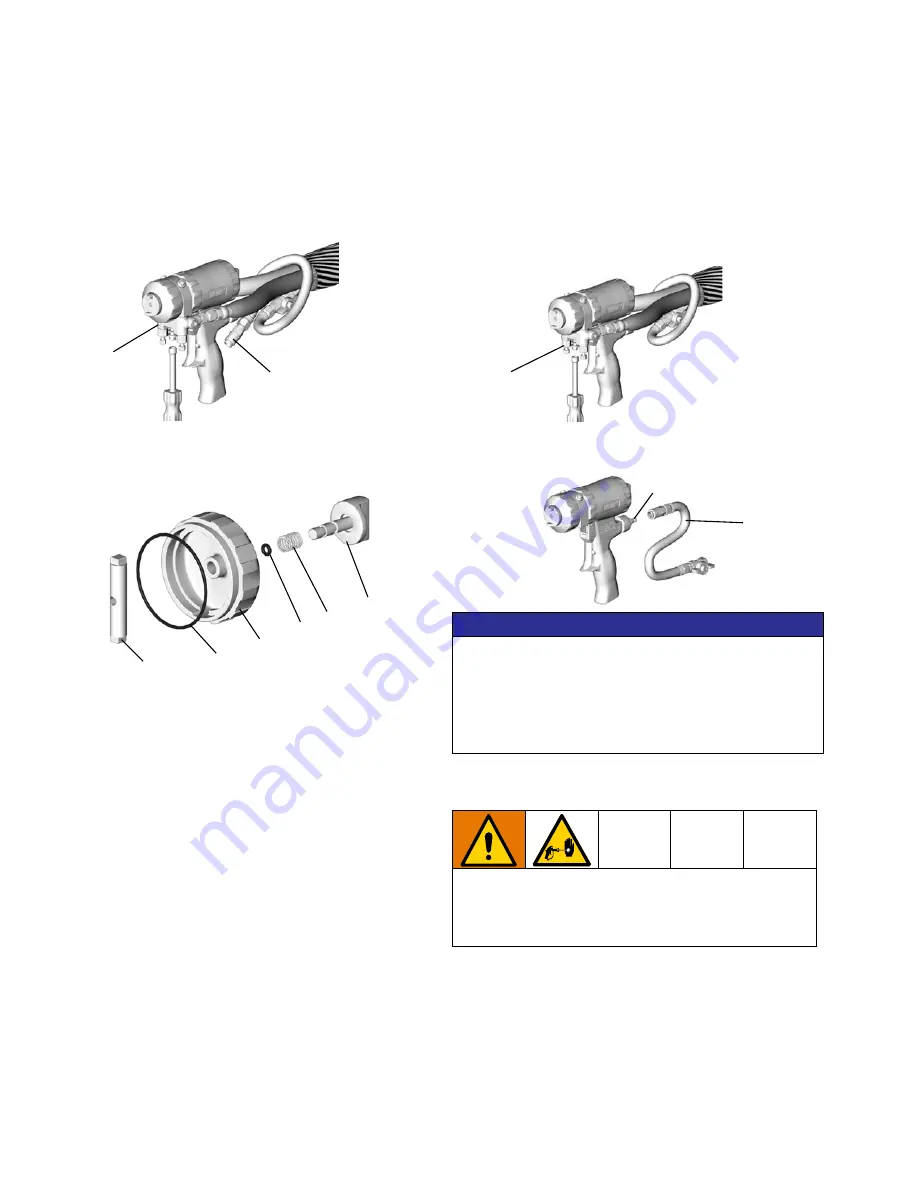

Inspect the Piston Safety Lock

1. Follow the

2. Disconnect air line quick coupler (D) and remove

fluid manifold (M).

3. Unscrew cylinder cap (5). Hold piston stop (28) with

wrench and unscrew from safety lock (4). Inspect

spring (30) and o-rings (14, 24).

4. Liberally lubricate o-rings and reassemble. Clean

threads with solvent or alcohol. Apply

medium-strength Loctite® or equivalent to threads

on stop (28) and reassemble.

5. Attach fluid manifold.

6. Connect air. Return gun to service.

Inspect the Check Valves

1. Follow the

2. Follow the

remove residual chemical.

3. Remove fluid manifold (M). Leave air connected.

4. Disconnect gun air whip hose (V) from air line quick

coupler (D).

5. Pry out check valves (26) at notch.

M

D

TI2554A

4

30

24

5

14

28

TI2433A

NOTICE

To prevent cross-contamination in the gun, do not

interchange A component (isocyanate) and B

component (resin) parts. Cross-contamination can

result in cured material in the gun. Cured material may

damage the sealing surfaces, block fluid passages,

and prevent gun function.

Damaged check o-rings (26f, 26g) may result in

external leakage. To avoid potential leakage and

serious injury from skin injection, replace any

damaged o-rings.

M

TI2543A

TI2540A

D

V