Installation

18

309550ZAP

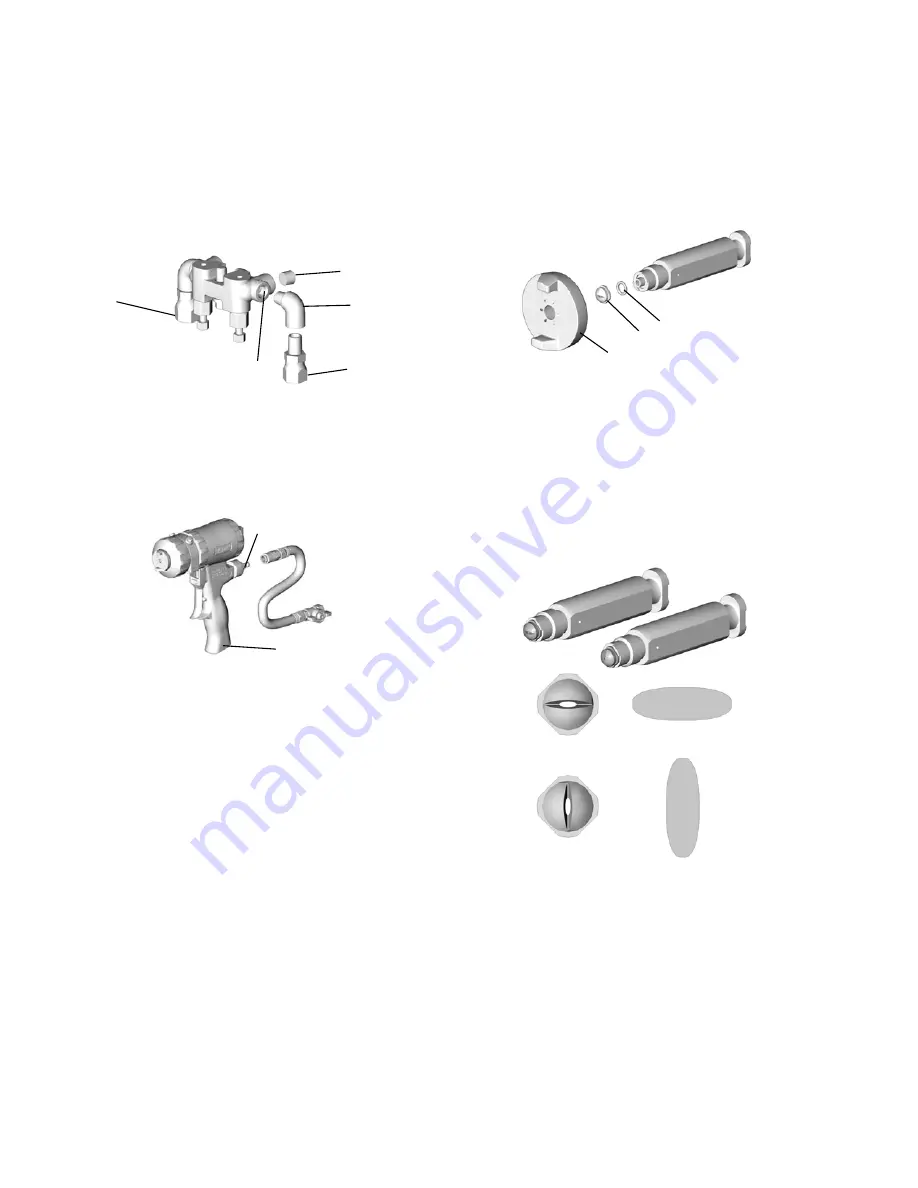

5. Apply thread sealant to plugs (12c), elbows (50*),

and male threads of fluid inlet swivels (S). Install

elbows (50*) in optional fluid inlets (P), facing down.

Install swivels (S) in elbows. Be sure to install A

swivel (smaller) in A side. Install included plugs

where swivels were located. Torque all parts to

235-245 in-lb (26.6-27.7 N•m).

*

Elbows (50) are not included with spatter spray gun.

6. Connect A and B hoses to A and B swivels.

7. Remove air line quick coupler (D) and optional air

inlet plug (J). Reverse positions. Apply thread

sealant and torque to 125-135 in-lb (14-15 N•m).

8. Reattach fluid manifold. Reconnect air. Return gun

to service.

Reposition or Replace Flat Spray Tips

1. Follow the

2. Remove air cap (10) and flat spray tip (39). Inspect

o-ring (40).

NOTE:

If tip is stuck, pry off with small screwdriver or

pull off with pliers. Tip is hardened to resist damage.

3. To clean, soak tip in compatible solvent, see

, page 22. Clean gently with tip

cleanout tool 15D234. Refer to

,

page 44, to fit tip configuration.

4. Reposition tip horizontally or vertically, or install

different tip size.

NOTE:

Tips marked on back with the last three digits of

,

5. Reinstall air cap hand tight.

NOTE:

The alignment of the clean off air ports on the air

cap does not affect operation.

S

50*

12c

S

P

TI2646A

D

J

TI2540A

40

39

10

TI2557A

TI2649A

TI2648A