Selection Charts

313516F

7

Proper Needle/Nozzle Selection

The spray gun's needle/nozzle kits range in

size to provide different fluid flow rates. As a

general guideline, use the fluid nozzle that will

give the required flow with the needle fully trig-

gered at a fluid pressure of 5–20 psi

(0.035–0.14 MPa, 0.35–1.4 bar).

•

For low flow rates or light viscosity fluid,

select the smaller nozzle sizes.

•

For high flow rates or high viscosity fluid,

select the larger nozzle sizes.

•

For abrasive fluids, the high wear gun mod-

els are recommended.

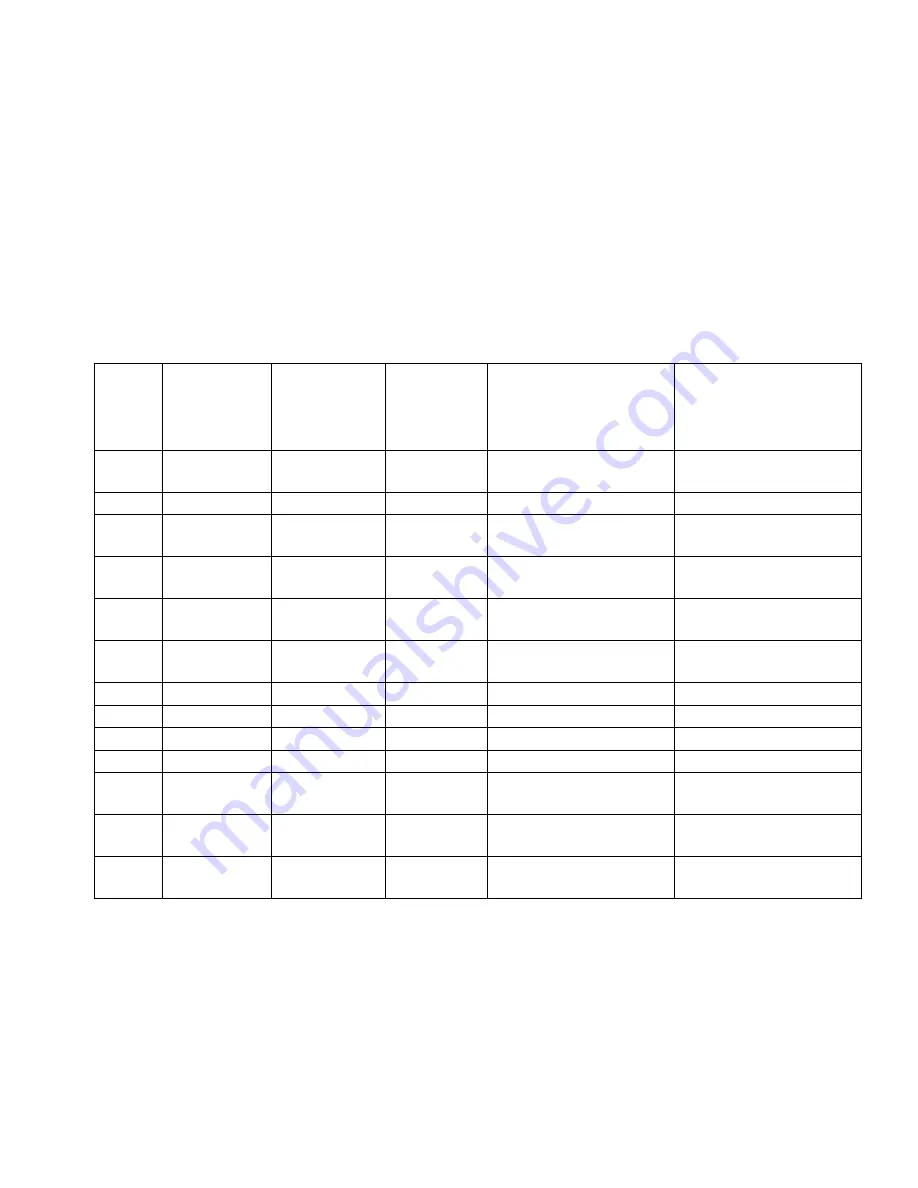

Air Caps

Air Cap

Part

No.

Type

Application

Nozzle

Orifice

in. (mm)

Atomizing Air

Max. HVLP/Compliant

Manifold Inlet Pressure

psi (MPa, bar)

Fan Air

Max. HVLP/Compliant

Manifold Inlet Pressure

psi (MPa, bar)

289773 Conventional General Metal

0.020–0.055

(0.5–1.4)

N/A

N/A

289784 Conventional General Metal

0.070 (1.8)

N/A

N/A

289041

HVLP

General Metal

0.020–0.070

(0.5–1.8)

17 (0.12, 1.2)

29 (0.20, 2.0)

289042

Compliant

General Metal

0.020–0.070

(0.5–1.8)

29 (0.20, 2.0)

33 (0.23, 2.3)

288861 Conventional

High Wear

0.059 (1.5)

N/A

N/A

289049 Conventional

High Wear

0.070–0.086

(1.8–2.2)

N/A

N/A

289115

HVLP

High Wear

0.059 (1.5)

18 (0.12, 1.2)

28 (0.19, 1.9)

289325

HVLP

High Wear

0.070 (1.8)

18 (0.12, 1.2)

27 (0.19, 1.9)

289050

Compliant

High Wear

0.059 (1.5)

28 (0.19, 1.9)

31 (0.21, 2.1)

289327

Compliant

High Wear

0.070 (1.8)

29 (0.20, 2.0)

32 (0.22, 2.2)

288862 Conventional

Wood

0.030–0.040

(0.8–1.0)

N/A

N/A

288864

HVLP

Wood

0.030–0.040

(0.8–1.0)

24 (0.17, 1.7)

26 (0.18, 1.8)

288863

Compliant

Wood

0.030–0.040

(0.8–1.0)

27 (0.19, 1.9)

42 (0.29, 2.9)