Air Flow

311051D

9

Air Flow

All tests were completed with the 0.055 in. (1.4

mm) nozzle and standard air cap for each gun

model.

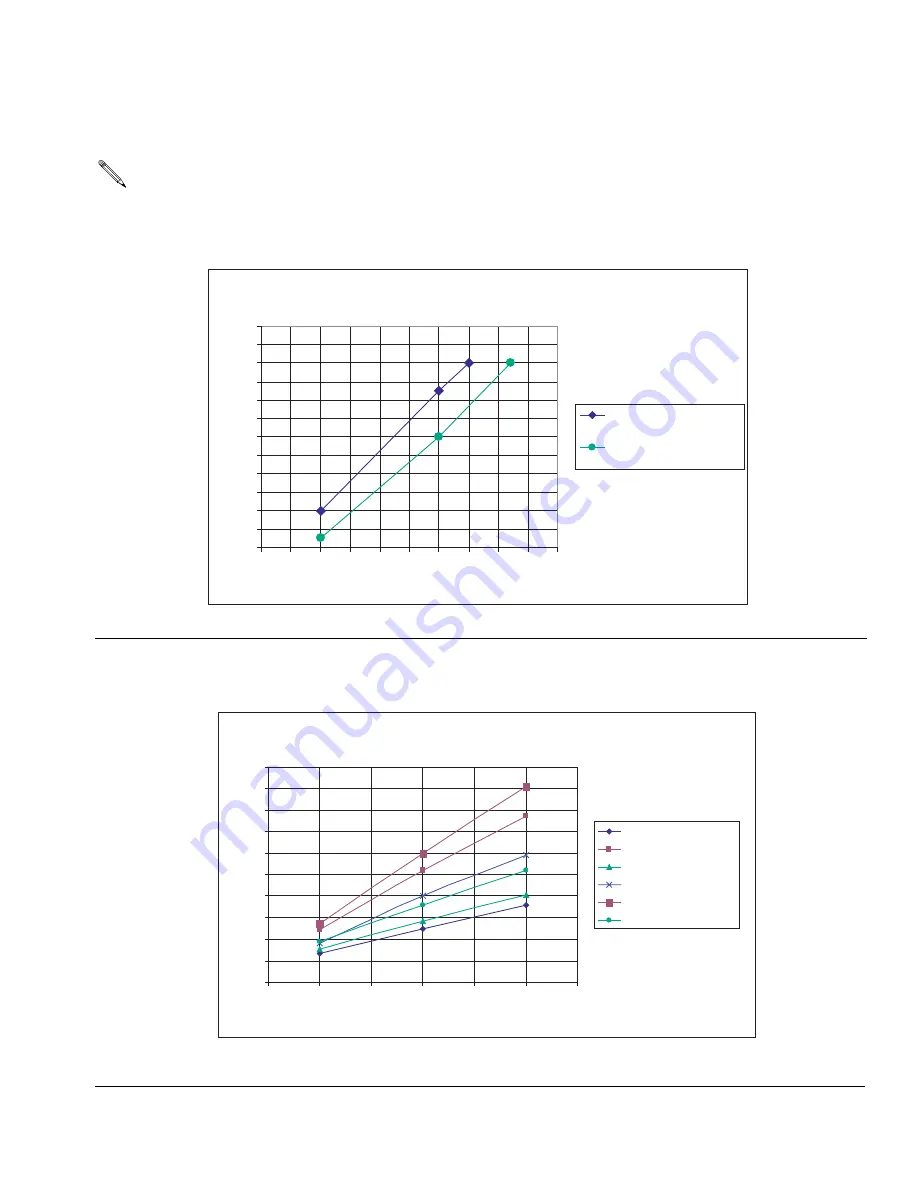

F

IG

. 1: HVLP Gun Air Cap Pressure

F

IG

. 2: Automatic Gun Air Consumption

HVLP Aircap Pressures

0

1

2

3

4

5

6

7

8

9

10

11

12

0

5

10

15

20

25

30

35

40

45

50

Manifold Inlet Pressure psi

A

ir

cap

P

ressu

re

i

n

p

si

HVLP Atomization Air

Pressure at Cap

HVLP Fan Air Pressure at

Cap

Automatic Gun Air Consumption

0

2

4

6

8

10

12

14

16

18

20

0

10

20

30

40

50

60

Manifold Inlet Pressure psi

A

ir

Fl

ow

i

n

S

C

FM

Airspray Atom. Flow

HVLP Atom. Flow

Compliant Atom. Flow

Airspray Fan Flow

HVLP Fan Flow

Compliant Fan Air Flow