Air Motor Repair

3A9121A

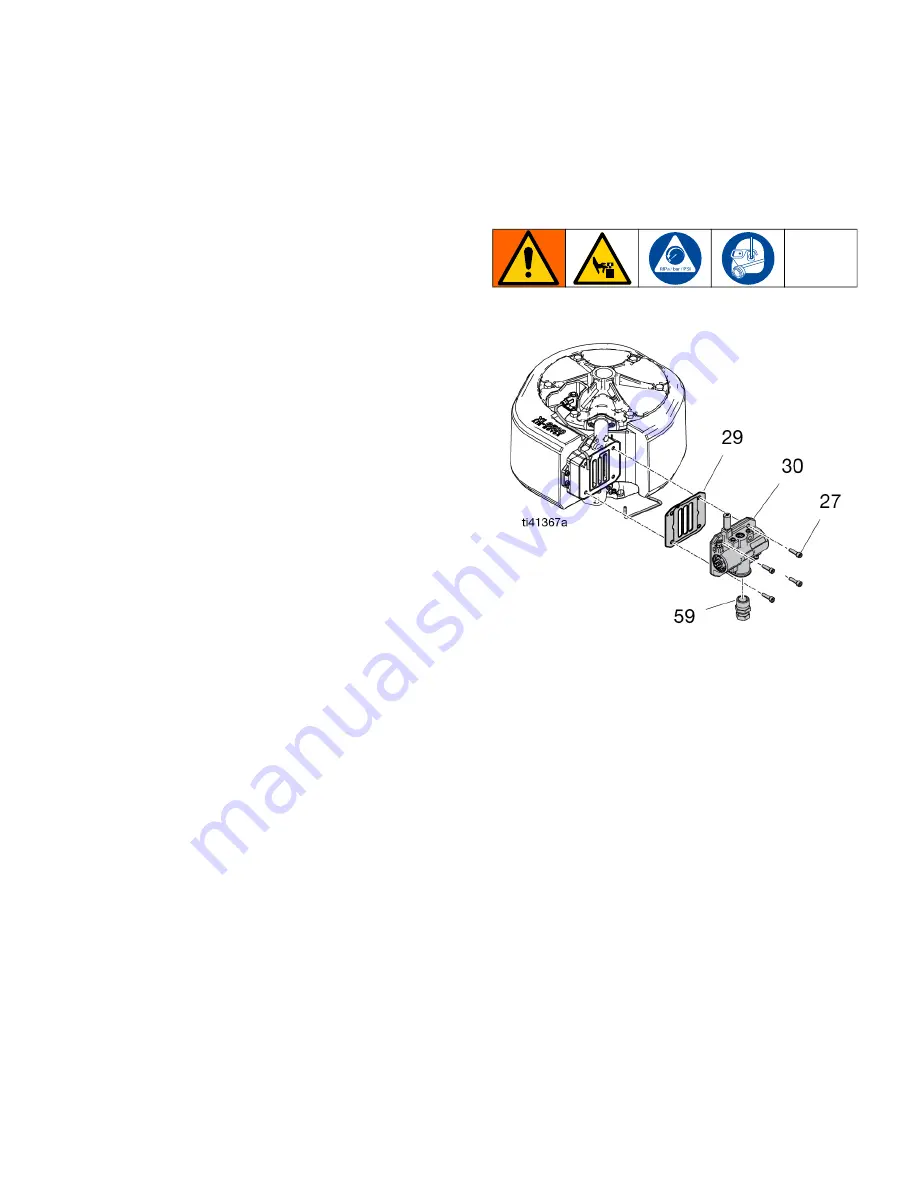

27

Air Motor Repair

Ice in Air Motor

When compressed air is exhausted, the sudden drop in

pressure causes the air temperature to drop below the

freezing point. This causes any water liquid or vapor to

turn to ice.

Higher air pressures pack high amounts of air and

water vapor in each cycle and create more expansion

and ice. Higher cycle rates also build up the ice and

lower the motor temperature faster. It is important to

select the correct motor and pump size to run at a

lower pressure, and cycle slower.

Warm humid climates can produce high levels of icing

because of the higher humidity levels. Low ambient

temperatures near freezing make it easier for the motor

parts to drop below freezing.

To minimize ice build-up:

•

Lower the dew point of the compressed air.

Use a

refrigerated air dryer, coalescing filter, or desiccant

filter to lower the water vapor content of the air.

•

Raise the compressed air temperature.

Warmer

air going in helps the motor parts stay above

freezing. Compressed air, especially at these

volumes, is warm when compressed. Keep the air

warm or stay near the compressor to reduce icing.

• Use the bleed air to clear ice build up.

Repair Air Valve

Replace Complete Air Valve

1. Stop the pump at the middle of its stroke. Follow

the

2. Disconnect air line to the motor.

3. Disconnect the air line to the motor and the pilot

valve lines to the air valve (30).

4. If installed on air motor, remove reed switch kit and

solenoid from air valve (30).

5. Use a 6mm Allen wrench to remove screws (27).

Remove the air valve (30) and gasket (29).

6. To install a replacement air valve, continue with

step 7. To repair the air valve, go to

, page 28, step 1.

7. Align the new air valve gasket (29) on the manifold,

then attach the air valve (30). Torque (27) to 80 +/-

in-lb.

NOTE:

Use grease to hold the gasket (29) in place. Be

sure the bleed air hole in the gasket aligns with the

bleed port in the valve manifold.