Operation

12

311320K

Clean Felt Wiper

1. Insert nozzle of flush can into holes of felt wiper.

2. Saturate felt with gun cleaner.

Initial Set Up

1. Remove coupling block from gun.

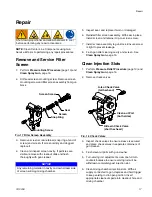

2. Check valving rod clearance in closed position. Rod

should extend approximately 1/32 in. (1 mm)

beyond tip of mixing chamber. If it does not, see

Valving Rod Adjustment

procedure, page 20.

3. Adjust valving rod travel to initial setting.

a. Loosen friction lock. Turn valving rod

adjustment screw clockwise until it stops.

b. Turn valving rod adjustment screw 11 turns

counterclockwise.

4. Connect air supply hose to gun.

5. Connect A-isocyanate hose (red-taped) to notched

fitting on coupling block. Then connect R-resin hose

(blue-taped) to fitting without notches on coupling

block.

6. Close both manual valves.

7. Pressurize the A and R chemical hoses and check

for leaks. (Refer to your proportioning system

manual.)

8. Bleed air from chemical hoses:

a. Hold coupling block with exit ports pointed into

disposable container.

b. Open each manual valve to allow trapped air to

escape. Bleed each side until chemical is free of

air.

c. Close both manual valves.

9. Use clean cloth soaked in gun cleaner to wipe clean

coupling block and its mating surfaces.

NOTE:

To avoid accumulation of dirt and other

contaminants, do not apply grease to mating surfaces of

coupling block.

10. Install coupling block to gun block.

11. Proceed with

procedure or

, page 13, procedure as required.

Daily Start-Up

1. Connect air supply to gun,

page 11.

2. Adjust air cap valve,

page 11.

3. Saturate felt in felt wiper with gun cleaner using

flush can.

4. Trigger gun multiple times to ensure valving rod

moves the full travel quickly and freely.

NOTE:

Sluggish valving rod action may result in valving

rod sticking in open position when fluid pressure is

applied. Always have a 5/16 in. nut driver available to

quickly close manual valves on coupling block.

5. Open both manual valves,

, page

F

IG

. 9 Valving Rod (Closed Position)

1/32 in.

Ensure gun is attached to coupling block and air

hose, and the proportioning unit is at desired

temperature and pressure.