8 308741

Setup

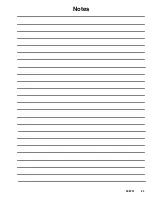

1. Connect the Air Line

NOTE:

D

You must install an air pressure regulator (F) on the

gun air line to control air pressure to the gun. See

Fig. 2.

D

If your regulated air source does not have a filter,

install an air filter (G) on the air line to ensure a dry,

clean air supply to the gun. Dirt and moisture can

ruin the appearance of your finished workpiece.

See Fig. 2.

D

Use a 5/16 inch (7.9 mm) I.D. air hose to minimize

excessive pressure drop in the hose. See the

Pressure Drop Chart

on page 11 for the expected

pressure drops through a 25 ft. (7.625 m) hose.

A.

Connect the air hose (D) to the 1/4 npsm gun air

inlet (C).

D

C

Fig. 1

7033A

B.

Connect the other end of the air hose (D) to a reg-

ulated air supply line (H).

NOTE:

Fig. 2 shows the filter (G) air regulator (F),

and air shut-off valve (E) on the air supply line.

01990

D

F

G

Fig. 2

H

E

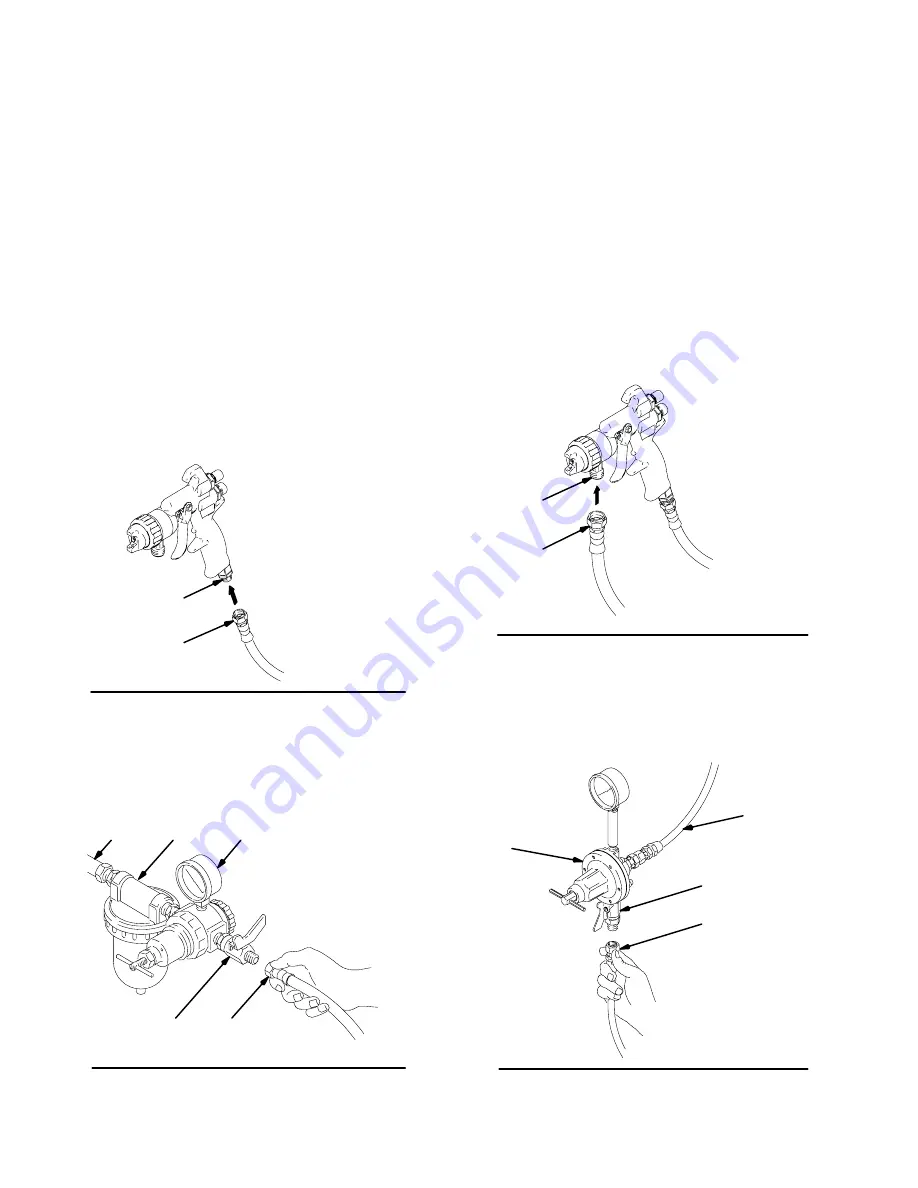

2. Connect the Fluid Hose

NOTE:

D

Before connecting the fluid line, blow it out with air

and flush it with solvent. Use solvent which is

compatible with the fluid to be sprayed.

D

Install a fluid regulator (L) on the fluid line to control

fluid pressure to the gun. See Fig. 4.

D

Filter the fluid line of coarse particles and sediment

to avoid clogging the fluid nozzle and causing

finishing defects.

A.

Connect the fluid hose (J) to the gun fluid inlet (B)

3/8–18 npsm [R 3/8–19] compound thread.

J

B

Fig. 3

7034A

B.

Connect the other end of the fluid hose (J) to a

regulated fluid supply line (K).

NOTE:

Fig. 4 shows the fluid regulator (L) and

fluid shut-off valve (M) on the fluid supply line (K).

J

L

Fig. 4

K

M

7016A

Summary of Contents for Delta Spray 239559

Page 23: ...308741 23 Notes ...

Page 31: ...308741 31 Notes ...