10

308152

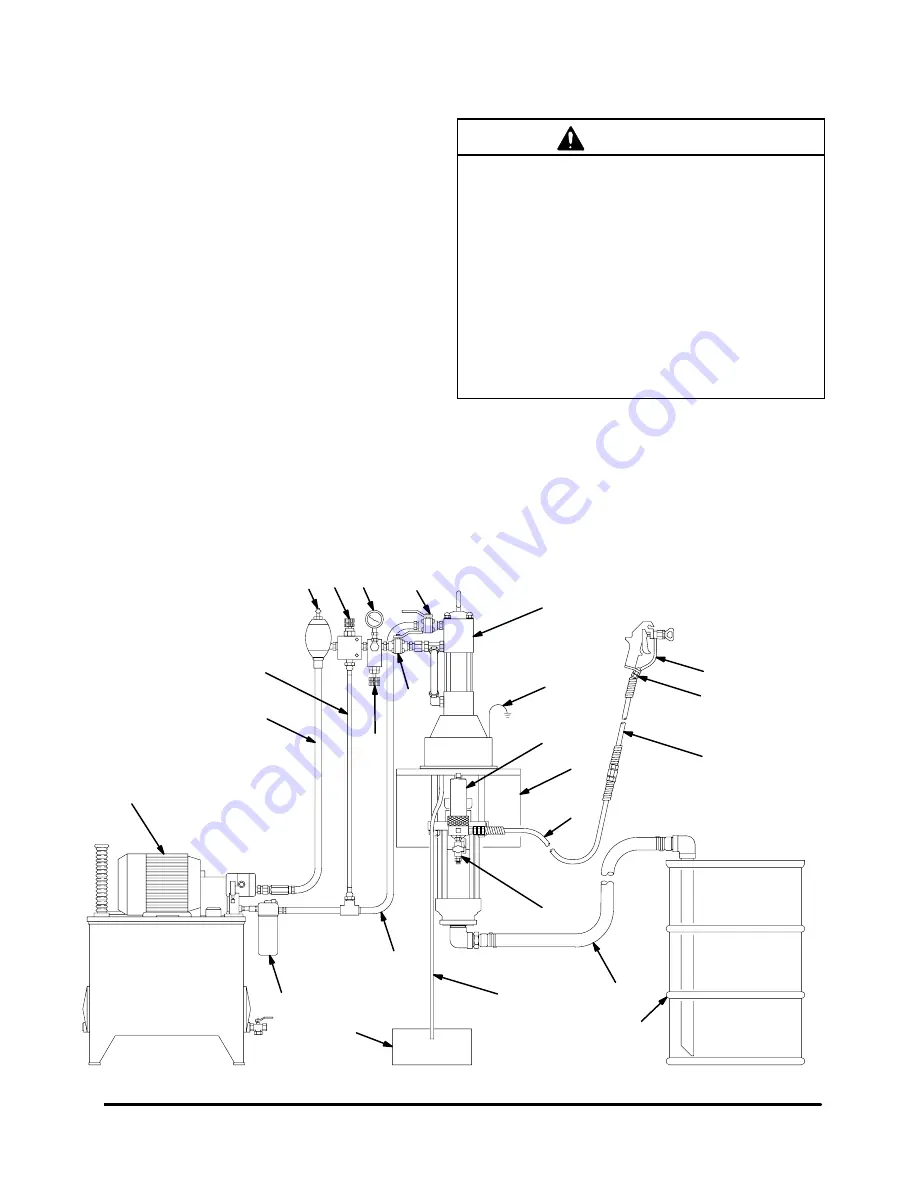

Installation

(HYDRAULIC-POWERED PUMPS)

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Accessories are available from your Graco

distributor. If you supply your own accessories, be sure

they are adequately sized and pressure-rated to meet

the system’s requirements.

Fig. 4 is only a guide for selecting and installing sys-

tem components and accessories. Contact your Graco

distributor for assistance in designing a system to suit

your particular needs.

CAUTION

Keep the hydraulic supply system clean at all times.

Be sure that all hydraulic fluid lines are absolutely

clean. Blow out the lines with air and flush thoroughly

with solvent before connecting to the hydraulic

motor, to avoid introducing harmful contaminants into

the motor. Plug the hydraulic lines immediately when

they are disconnected.

Do not exceed 37.8 liter/min (10 gpm) hydraulic oil

volume to the motor, to avoid stalling the pump.

For optimum pump performance, keep the tempera-

ture of the hydraulic oil below 54

_

C (130

_

F).

Fig. 4

0627B

KEY

A

Pump

B

Wall Bracket

C

Hydraulic Supply Line

D

Hydraulic Return Line

E

Drain Line (from pressure reducing valve)

F

Pressure Gauge

G

Flow Control Valve

H

Pressure Reducing Valve

J

Accumulator

K

Drain Line (from motor drip pan)

L

Fluid Filter

M

Fluid Drain Valve (required)

N

Electrically Conductive

Fluid Supply Hose

P

Fluid Whip Hose

R

Gun/Valve Swivel

S

Airless Spray Gun or Dispensing Valve

T

Drum Suction Kit

U

Hydraulic Supply Line Shutoff Valve

V

Hydraulic Return Line Shutoff Valve

Y

Ground Wire (required, see page 7 for

installation instructions)

AA Hydraulic Return Line Filter

A

B

D

E

F

G

H

J

K

M

N

P

Y

200 LITER

(55 GAL.)

DRUM

L

R

S

T

U

C

V

HYDRAULIC

POWER SUPPLY

DRAINAGE

CONTAINER

AA

TYPICAL INSTALLATION

Summary of Contents for Dura-Flo 2400

Page 6: ...6 308152 Notes ...

Page 12: ...12 308152 Notes ...