Electric Motor

3A2247A

21

3 Phase, 400 VAC, 50 Hz, Electric Motor

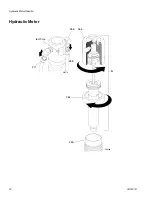

1.

Install pulley (43) and tighten set screws. Torque set

screws to 60 in-lb (6.8 N•m). Make sure pulley is

flush with end of electric motor shaft.

2.

Install four screws (23), nuts (174) and electric

motor to motor mounting bracket (99). Motor should

be centered in motor slots. Torque screws to 225

in-lb (25.4 N•m).

3.

Install four screws (30), nuts (174) and handle (175)

to motor mounting bracket (99). Torque screws to

225 in-lb (25.4 N•m).

4.

Remove motor junction box cover (J).

5.

Remove strain relief fitting (S) from motor junction

box cover (J).

6.

Slide strain relief fitting (S) over motor cable power

leads.

7.

Screw strain relief fitting (5) into motor junction box

cover (J).

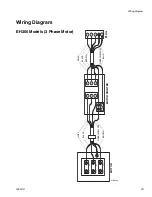

8.

Be sure gasket is in position on motor junction box

cover. Connect three power leads and ground. Con-

nect yellow and green ground wire to motor junction

box ground connection. Connect power leads as fol-

lows:

• Brown wire to motor terminal U1

• Black wire to motor terminal V1

• Grey wire to motor terminal W1

See

Wiring Diagram

, page 29, for connection

locations. Torque power leads to 28 in-lb (3.2 N•m).

Torque ground lead to 28 in-lb (3.2 N•m).

9.

Install motor junction box cover (J) to motor junction

box. Torque junction box cover to 28 in-lb (3.2 N•m).

10. Install motor assembly on sprayer.

204

205

43

30

119

175

30

190

192

191

193

ti18617a

200

198

ti18696a

NOTICE

Make sure wires are completely inside motor junction

box and will not be pinched between motor junction

box and motor junction box cover. Wires will be dam-

aged and create an electrical hazard if pinched.

ti18700a

S

J

ti18748a