Position

Position

Position Sensor

Sensor

Sensor Replacement

Replacement

Replacement

(24W120)

(24W120)

(24W120)

NOTICE

NOTICE

NOTICE

To avoid damage to the encoder and control board,

wear grounding strap (Graco Part No. 112190 –

not supplied) and ground appropriately.

Overview

Overview

Overview

The position sensor is used to determine where the

driver output shaft (H) is in the stroke.

Tools

Tools

Tools Required

Required

Required

• 6 mm Hex Wrenches

• 13 mm Open-Ended Wrench

• 6 mm Open-Ended Wrench

• Phillips Screwdriver (#2)

• Torque Wrench (15 ft-lb, 20 N•m)

Prepare

Prepare

Prepare Driver

Driver

Driver

1.

Remove power from the driver. Follow

appropriate lock-out/tag-out procedures. Wait

five minutes before servicing.

2.

Follow the

Pressure Relief Procedure, page 8

.

3.

Decouple the pump lower from the driver per the

system manual.

Remove

Remove

Remove Electronics

Electronics

Electronics Cover

Cover

Cover

NOTICE

NOTICE

NOTICE

To avoid equipment damage, carefully support the

cover when removing the last bolt. Hold the cover

horizontally and take care that the wires are not

pulled tight.

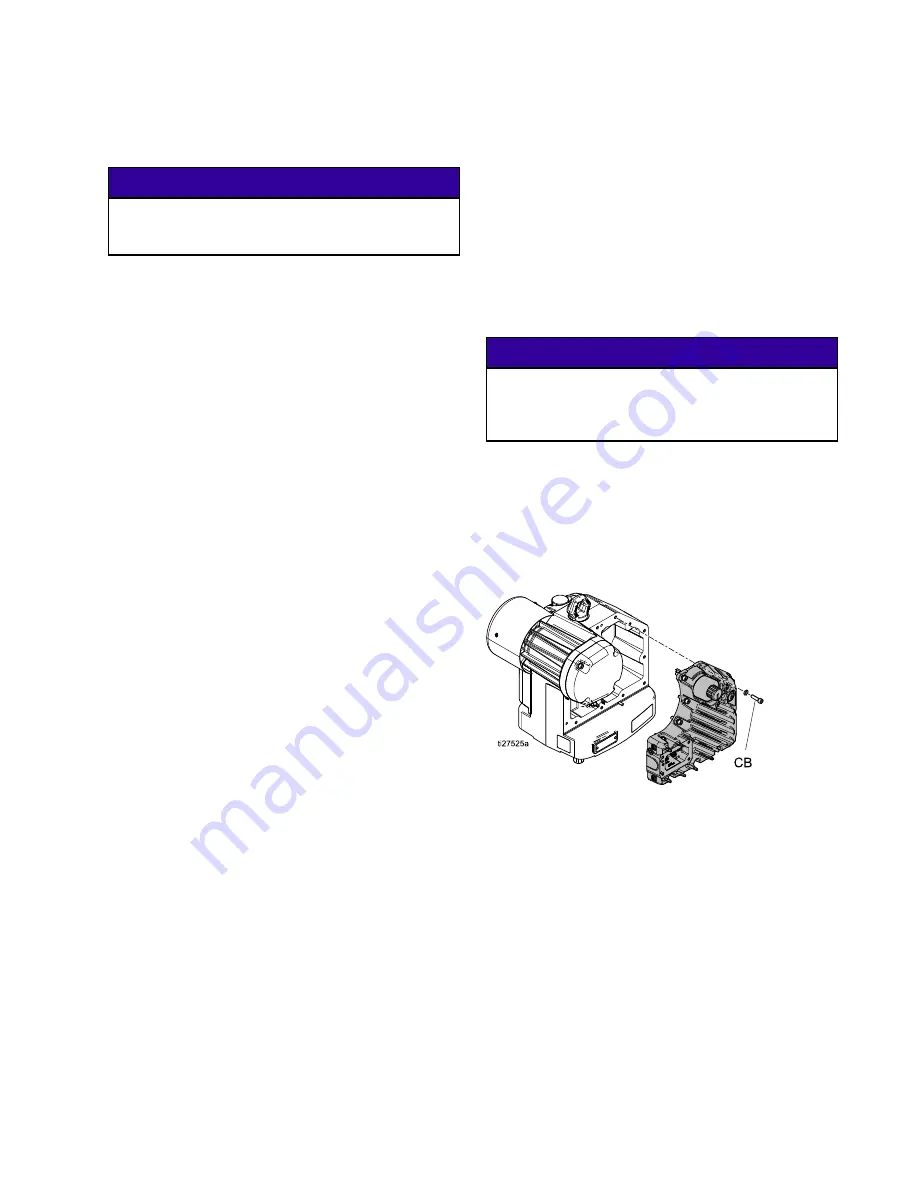

1.

Remove the 12 bolts (CB) that hold on the

electronics cover using a 6 mm hex wrench.

Place bolts in a safe location.

2.

Pull the cover straight off of the alignment pins

that hold the cover in place.

3.

Support the cover after it has been removed to

prevent putting excess strain on the wires inside.

3A5124B

19