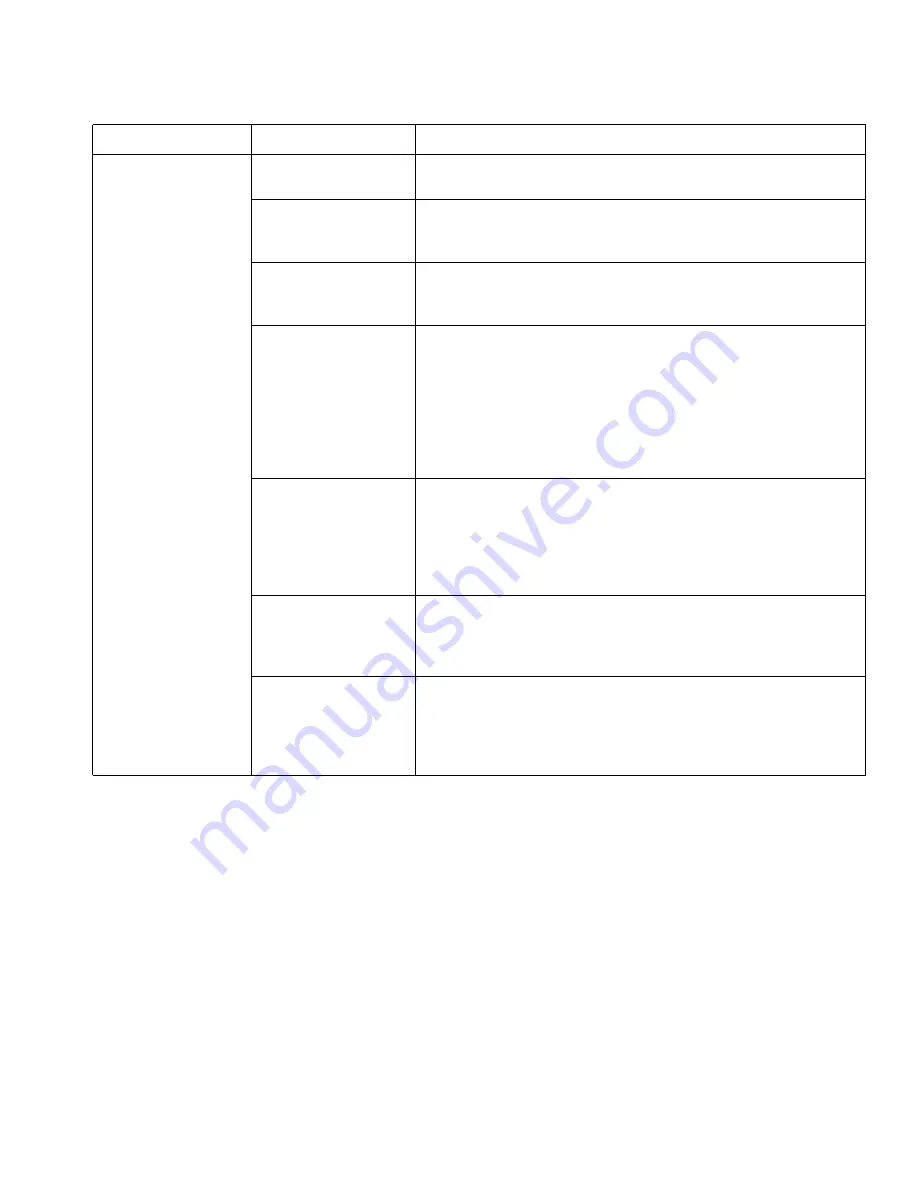

Troubleshooting

3A7467C

33

While in BLAST

mode, with the blast

control switch (B)

engaged, air is flowing

from the nozzle but

little or no abrasive is

flowing from the

nozzle.

The abrasive ball valve

is closed.

See

The abrasive metering

valve is not properly

set.

See

The pot does not have

a sufficient amount of

abrasive.

See

The pinch valve does

not open.

Engage the blast control switch (B) and check for actuation of the

pinch valve. If there is no actuation, disconnect the orange tubing

at the pinch valve. If the pinch valve opens and source air is

coming from the orange tubing, confirm that the tubing is correctly

routed. If the pinch valve does not open, replace it. If the pinch

valve opens and there is no source air coming from the tubing,

inspect the mufflers on the 4-way valve for debris. If debris is not

present, clean or replace the 4-way valve.

There is an obstruction

inside the pot or inside

the abrasive hose

between the pot and

the enclosure.

Follow

, page

12. With the abrasive hose disconnected, inspect the interior of the

pinch hose for obstructions or debris and replace if necessary (see

, page 38). Remove the tri-clamp from

the bottom of the pot. Inspect the bottom of the pot and the

abrasive hose for obstructions or debris.

The pot pressure is too

low.

With the blast control disengaged, allow the pot to pressurize and

wait for the pump to stall. If the pot pressure gauge does not reach

185 psi (12.75 bar, 1.275 MPa), see the “Unable to fill or

pressurize the pot with water” problem listed on this table.

The blast pressure is

too high.

If the blast pressure gauge reads 160 psi (11.03 bar, 1.10 MPa) or

greater, it may not be possible to achieve than 15 CPM on the

MediaTrak. This is more common with fine mesh abrasive usage.

Decrease the blast pressure to 100 psi (6.9 bar, 0.69 MPa) to see

if CMP can be increased.

Problem

Cause

Solution

Summary of Contents for EcoQuip 2 EQ200t Elite

Page 9: ...Warnings 3A7467C 9...

Page 10: ...Component Identification 10 3A7467C Component Identification WL D WLL D 3 1 4 5 6 7 8 9 0...

Page 39: ...Repair 3A7467C 39...

Page 46: ...Parts 46 3A7467C EQ200T Parts WL F 1 Apply thread sealant to all non swivel pipe threads...

Page 48: ...Parts 48 3A7467C EQ400T Parts 1 Apply thread sealant to all non swivel pipe threads...