How to Spray

3A5097D

17

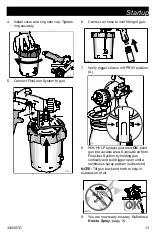

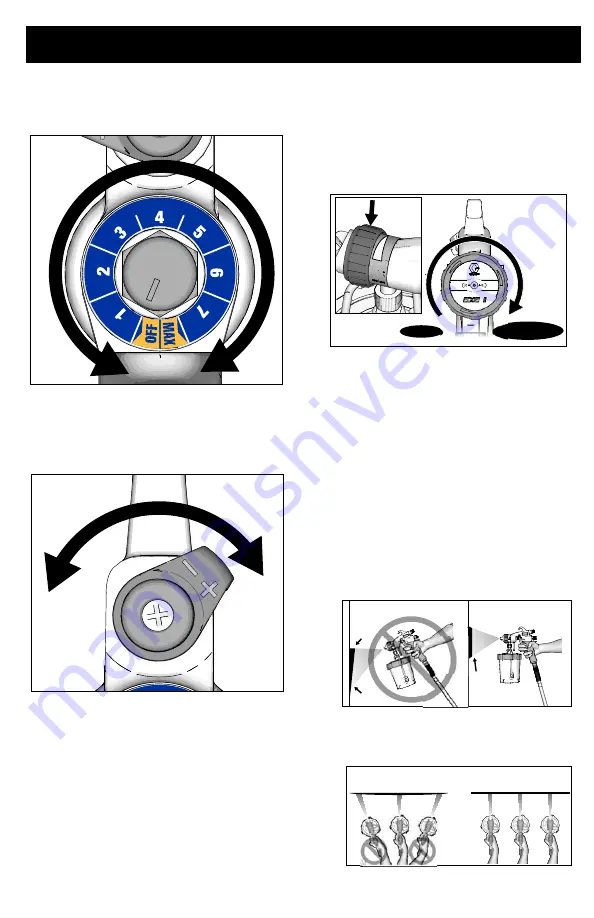

Fluid Control:

Set knob to OFF. Increase fluid until desired

flow is attained.

Air Control:

Start with air control at the

+

position. To

decrease atomization of fluid, adjust air

control toward the

-

position.

Pattern Size Control:

Additional control of the pattern size is

available by rotation of the air cap retaining

ring. Start with the fluid nozzle flush with the

center surface of the air cap. Pattern size can

be adjusted by rotating the retaining ring in

either direction.

Spray Techniques

Use a piece of scrap cardboard to practice

spraying techniques before spraying the

work piece.

•

Always spray with the least amount of

pressure required to provide the desired

spray pattern and rate of application.

Spraying at pressures higher than

necessary wastes material and can

result in an orange peel finish.

•

Aim gun straight at surface. Tilting gun to

direct spray angle causes an uneven

finish.

•

Flex wrist to keep gun pointed straight.

Fanning gun to direct spray at angle

causes uneven finish.

F L

U I D

ti30980b

L U I

ti30980a

ti30981a

THICK

UNEVEN FINISH

EVEN FINISH

THIN

EVEN

ti30761a

UNEVEN FINISH

EVEN FINISH

THICK

THIN

THIN

ti30762a

Summary of Contents for Edge II 17R236

Page 34: ...Notes 34 3A5097D Notes ...