4. Cleaning a Clogged Tip

-------WARNING-----

To reduce the risk of serious bodily injury from in

jection, use extreme caution when cleaning or

changing spray tips. If the spray tip clogs while

spraying, engage the gun safety latch immediate-

ly. Then follow the procedure below.

NEVER wipe off build-up around the spray tip until

pressure is fully relieved and the gun safety latch is

engaged.

a. Clean the front of the tip frequently during the

day's operation.

First,

follow the

Pressure

Relief Procedure Warning

on page 10. Then

use a solvent-soaked brush to keep fluid from

building up and clogging the tip.

b. If the spray tip does clog, release the gun trig

ger, and engage the gun safety latch.

c.

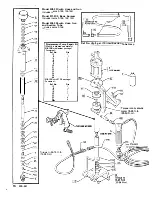

Model 226-333 and 226-336 only

Rotate the RAC IV handle 180

°

. See Fig 6.

Disengage the gun safety and trigger the gun

into a grounded waste container. Engage the

gun safety again. Return the handle to the

original position.

Model 23 7-003 only

VERY SLOWLY loosen the tip guard retaining

nut or hose end coupling, and relieve pressure

gradually, then loosen completely. Clear the tip

or hose, then reassemble.

d. Disengage the gun safety, and resume spraying.

e.

If the tip is still clogged,

engage the gun safety,

shutoff and unplug the sprayer, and open the

drain valve to relieve pressure. Remove the

spray tip and clean it.

Model 226-333 and 226-336 only

Instructions for cleaning the RAV IV are given

in manual 307-848.

MAINTENANCE

1.

Check the packing nut/wet-cup daily.

First

follow the

Pressure Relief Procedure Warning

·on page 10. Be sure the wet-cup is 1/3 full of TSL

at all times to help prevent fluid buildup on the

piston rod and premature wear of packings. The

packing nut should be tight enough to stop

leakage, but no tighter. Overtightening may cause

binding and excessive packing wear. Use a 1/4 in.

diameter rod to adjust the nut.

NOTE:

Normal seepage of hydraulic fluid past the

hydraulic motor piston rod wiper will

gradually fill the wet-cup. Check the wet

cup every eight hours to prevent overflow.

2.

Clean the fluid filter often

and whenever the

sprayer is stored. First follow the

Pressure Relief

Procedure Warning

on page 10. Refer to manual

307-273, supplied, for the cleaning procedure.

3.

Flush the sprayer at the end of each work day

and fill it with mineral spirits to help prevent pump

corrosion and freezing. See "Flushing Guidelines"

on page 9.

-------CAUTION------.....

To help prevent pump corrosion and to avoid

freezing, never leave water in the sprayer. Freez

ing can seriously damage the pump.

4. For very short shutoff periods,

leave the suction

tube in the paint, follow the

Pressure Relief Pro

cedure Warning

on page 10, and clean the spray

tip.

5.

Coil the hose

around the hose brackets when stor

ing the sprayer, even for overnight, to help protect

hose from damage.

.-------WARNING------

To reduce the risk of component rupture which

can cause serious bodily injury, NEVER use worn

or damaged hoses. Refer to the

Hose Safety

Warning

on page 3.

Fig 6------------------

6.

Check the hydraulic fluid level

occasionally.

Add fluid as necessary to keep the fluid level be

tween the ADD and FULL rnarks on the dipstick.

Refer to page 8.

7.

Change the hydraulic fluid

every 2000 hours of

operation or every 12 months, whichever comes

first. Also clean the hydraulic pump intake filter and

replace the disposable filter in the return line.

First,

follow the

Pressure Relief Procedure Warning

on page 10, then remove the sprayer shield and

follow the instructions under "Replacing the Elec

tric Motor", page 14, to get at the filters, remove

the old hydraulic fluid and clean the sump.

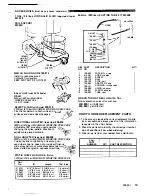

8. Relieve fluid pressure when not using the sprayer to

avoid the pump stalling out at the top of its stroke.

If the pump stalls, follow the

Pressure Relief Pro

cedure Warning

on page 10, remove the plug

from the top of the hydraulic motor and push the

spool all the way down. See Fig 7. Replace the plug

and restart the sprayer.

Fig 7-----------------

9. Periodically, or if electric motor is overheating,

unplug unit, follow

Pressure Relief Procedure

Warning,

page 10, remove shield and clean all

paint, dirt, dust, etc., off the shield, fan blades,

motor and cooling fin�.

306-941

11