308-088

To reduce the risk of serious bodily injury, including

fluid injection; splashing in the eyes; injury from

moving parts or electric shock, always follow the

%&&'% "! %$'% %#!#

on page 11

before continuing.

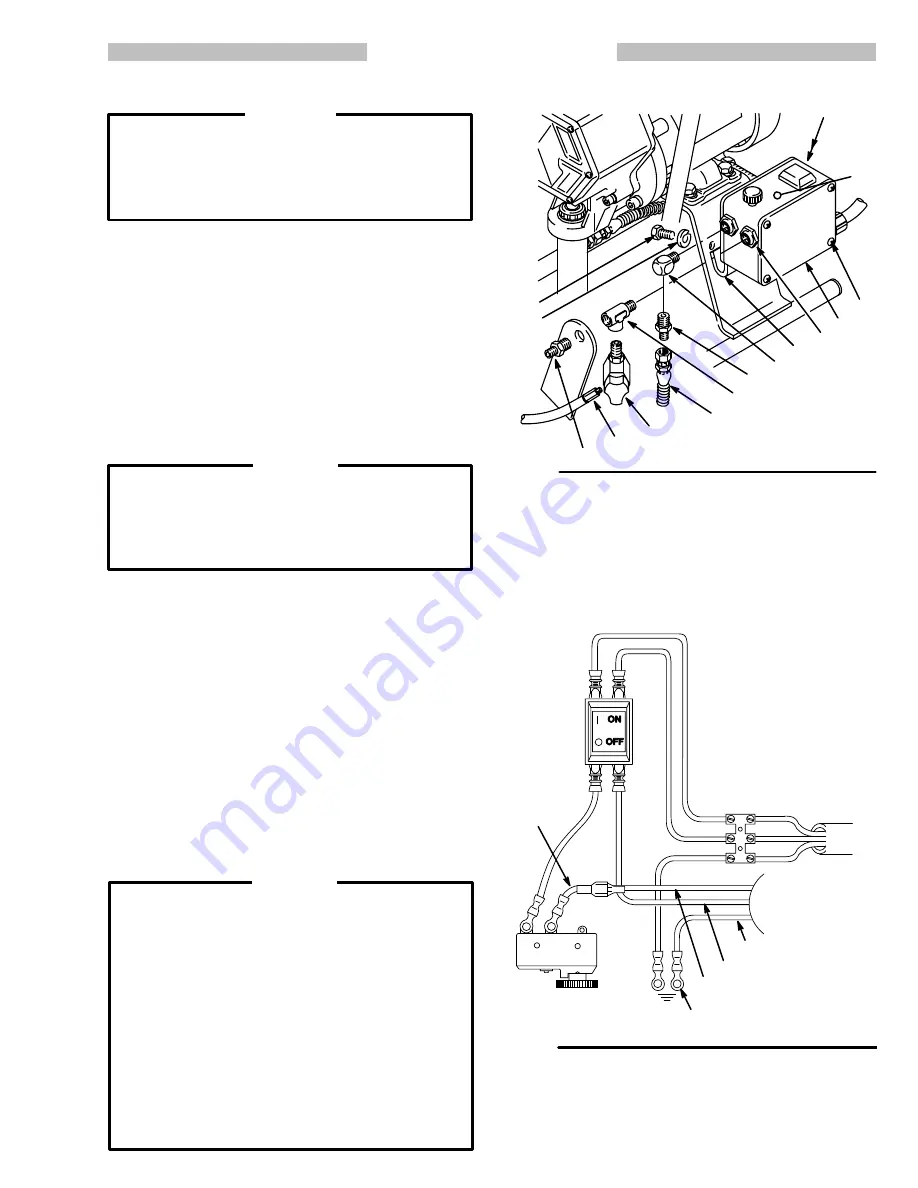

Refer to Fig 20 except where noted otherwise.

1 Disconnect the hose (26) from the pressure control

nipple (30).

2 Remove the screws (3) and cover (17) from the presĆ

sure control (18).

3 Disconnect the motor leads.

4 At the pressure control, unscrew the nut on the conĆ

duit connector (305).

5 Remove the screws (68) and pull the pressure conĆ

trol away from the frame, carefully guiding the motor

leads through the connector (305).

Use extreme caution when removing the tee (11) or

any other fitting from the pressure control. Any

twisting or jarring of the pressure control fitting

could alter the factory setting of the control or perĆ

manently damage the control.

6 Remove the tee (11), nipple (30) and drain valve

(35,36) from the old pressure control.

Hold the nut (A) firmly at the pressure control with a

wrench and rotate the tee 90

counterclockwise to

move the drain valve away from the sprayer. This

provides clearance to remove the drain valve from

the tee. Remove the tee (11) and nipple assembly.

Install these parts in the new pressure control in the

reverse order.

7 Remove the mounting bracket (52) and install it on

the new pressure control.

8 Replace the pressure control in the reverse order of

disassembly.

The harness adapter (13g) is used only with a reĆ

placement motor.

Failure to observe the following may cause poor

performance or excessive pressure and permaĆ

nent damage to the pressure control:

1. Always use nylon spray hose at 15.2 m (50 ft)

minimum length.

2. Never use a wire braid spray hose.

3. Never attach a spray hose to the pressure

drain valve.

4. Never add any type of shutoff device between

the pump outlet and the spray gun.

5. Never allow flushing water or water base paint

to freeze in the system.

69

30

11

26

35

36

30

68

39

305

!

3

17

18

52

MICROSWITCH

ON/OFF

SWITCH

POWER

CORD

BROWN

BLUE

GRN/YEL

MOTOR LEADS

ATTACH TO

GROUNDING SCREW (302)

!

13g

Summary of Contents for EM 390

Page 4: ... 0 0 2 6635 9 1 0 7 4 2 322 7 7 36 2 82 0 0 0 0 0 0 0 0 0 0 2 1 0 0 0 0 ...

Page 14: ... 0 0 0 ...

Page 16: ... ...

Page 20: ... ...

Page 23: ... ...

Page 25: ... ...

Page 26: ... 0 1 0 0 0 1 6 2 0 3 0 7 7 7 2 3 1 021 1 4 5 2 1 0 6 0 ...

Page 27: ... ...