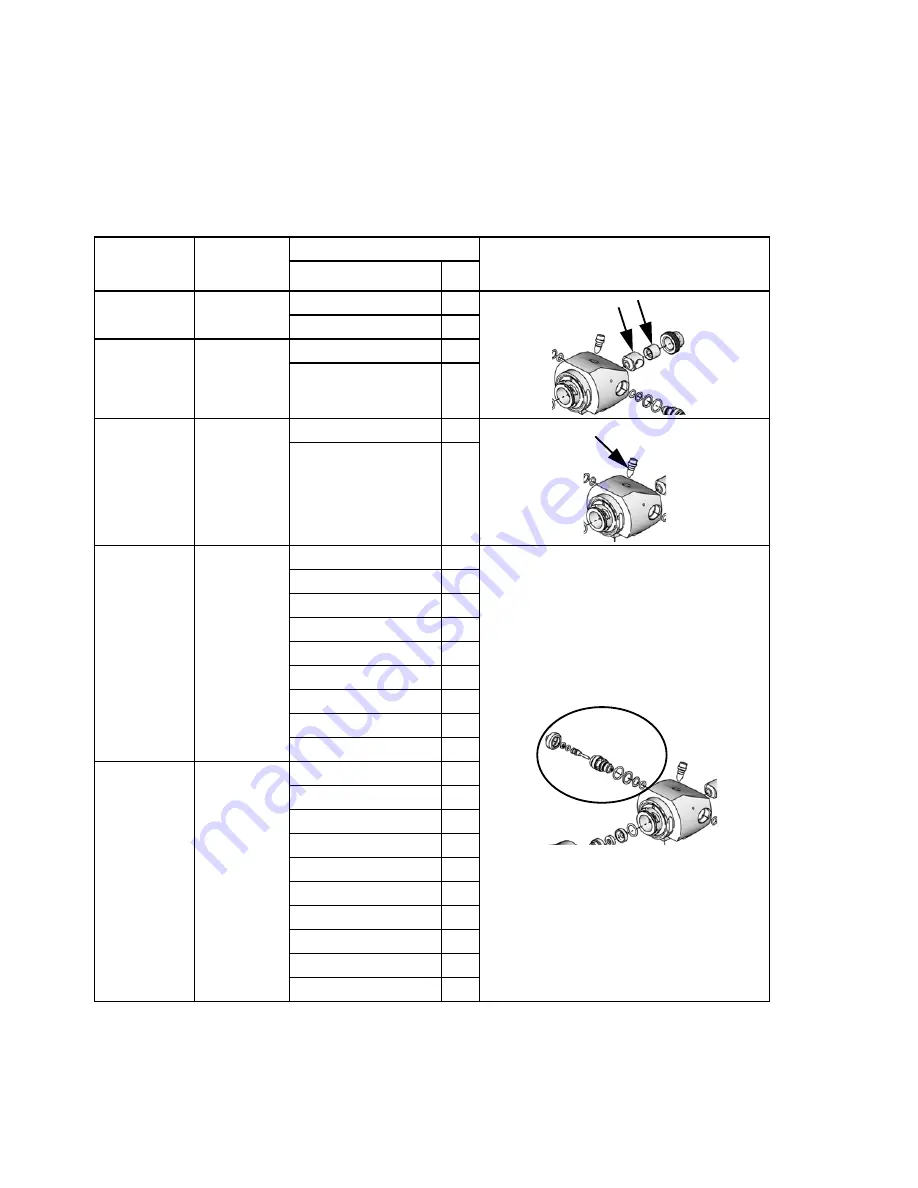

Kits

313872B

45

Kits

See

Maintenance

on page 24 and

Repair

on page 31

for appropriate kit installation procedures. See

Com-

plete O-ring Placement Guide

on page 52 for o-ring

identification help.

Kit

Description

Kit Number

Parts included in Kit

Illustration

Description

Qty

250 Mix

Chamber

24D314

Mix Chamber

1

Front Bearing

1

375 Mix

Chamber

24D322

Mix Chamber

1

Front Bearing

1

Throat Seal

Liquid Bleed

Port O-Ring

Kit

246354

O-Ring

6

O-Ring Installation

Tool

1

250 Iso Ori-

fice

24D223 -

24D238;

see

Orifice

Kits

on

page 50

Orifice Housing

1

O-Ring

1

O-Ring

1

O-Ring

1

Needle

1

Backup Ring

1

O-Ring

1

Iso Orifice Cap

1

Cleanout Drill

1

375 Iso Ori-

fice

24D239 -

24D254;

see

Orifice

Kits

on

page 50

Orifice Housing

1

O-Ring

1

O-Ring

1

O-Ring

1

Needle

1

Backup Ring

1

O-Ring

1

Iso Orifice Cap

1

Orifice Spacer

1

Cleanout Drill

1