Service

6

3A5053B

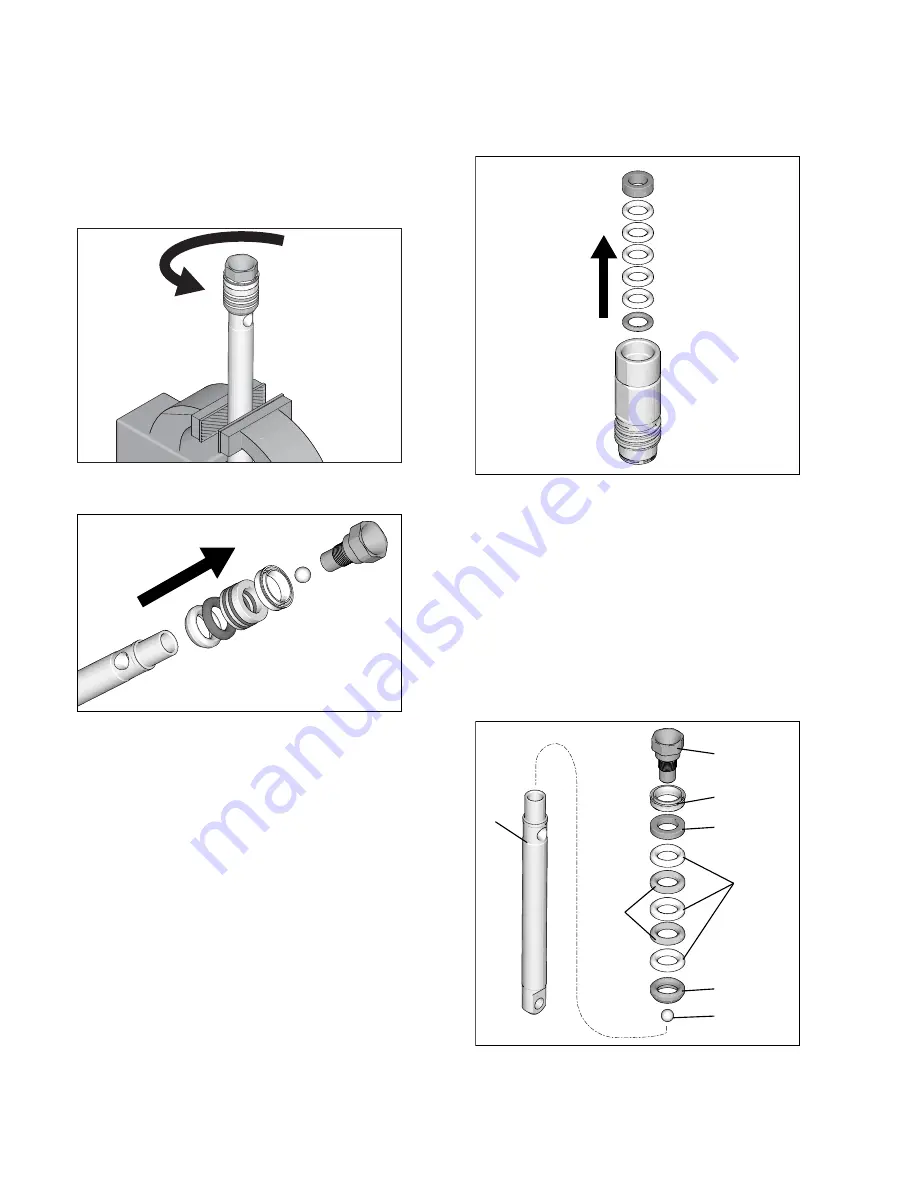

5. Unscrew piston valve from piston rod. Clean and

inspect parts. The piston has a special thread lock-

ing/sealing patch. Do not remove the patch. The

patch allows four disassembly/assembly procedures

before it is necessary to apply medium strength

threadlocker to the threads.

6. Remove packings and glands from piston rod.

7. Remove throat packings and glands from cylinder.

Discard throat packings and glands.

Assemble

1. Soak all leather packings in SAE 30W oil for 1 hour

minimum prior to assembly. Stack male gland (219)

on piston rod. Alternately stack UHMWPE (208) and

leather (218) packings (note orientation) on piston

rod. Install female gland (209). Install piston wiper

(217) (note orientation) on piston valve, threads are

good for four repackings. Use medium strength

threadlocker on piston valve threads after four

repackings.

ti31050a

ti31062a

ti31052a

210

217

209

208

218

219

206

222

ti31051a