Operation

334730F

17

Operation

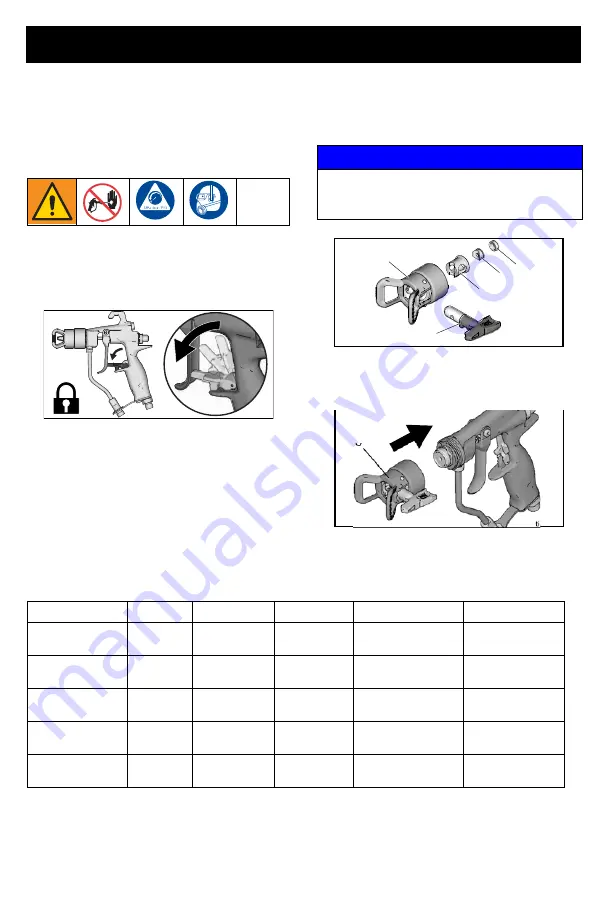

Spray Tip Installation

1.

Perform

2.

Engage trigger lock.

3.

Insert seat (33a) into seat housing (35).

4.

Insert seat housing (35) into air cap (6).

5.

Insert seal (33b) over seat (33a). Use

black seal for water-based materials and

orange seal for solvent and oil-based

materials.

6.

Insert tip into slot (a) in air cap (6).

7.

Install air cap over end of gun. Hand

tighten.

Tip Selection

ti25450a

NOTICE

If air cap is not fully installed on gun, fluid

pressure can force paint into air line and dam-

age sprayer.

ti25475a

6

35

33a

33b

33

ti25474a

6

Material

Oil Based Water Based

Tip Size

Fluid Setting

Air setting

Stains/Varnish

.008/.010

500-700 psi

(34-48 bar)

10-15 psi

(0.7-1.0 bar)

Lacquers

.008/.010

700-1000 psi

(48-69 bar)

10-15 psi

(0.7-1.0 bar)

DTM

.010/.012

900-1200 psi

(62-83 bar)

15-20 psi

(1.0-1.4 bar)

DTM (Alkyd)

0.14/0.16

1800-2400 psi

(124-165 bar)

20-25 psi

(1.4-1.7 bar)

Enamels

0.14/0.16

1800-2400 psi

(124-165 bar)

25-30 psi

(1.7-2.1 bar)