4

307–633

INSTALLATION

NOTE: Numbers and letters in parentheses in the text

correspond to the reference numbers and letters

in the drawings and parts list.

Be sure your system has a bleed-type master air

valve (pneumatic pumps only) and a fluid drain

valve. These two accessories help reduce the risk

of serious bodily injury, including fluid injection,

splashing in the eyes or on the skin, or injury from

moving parts, if you are adjusting or repairing the

pump or gun.

1.

The bleed-type master air valve relieves air

trapped between this valve and the pump after

the air regulator is shut off. Trapped air can

cause the pump to cycle unexpectedly.

2.

The fluid drain valve assists in relieving fluid

pressure in the displacement pump, hose and

gun; triggering the gun to relieve pressure may

not be sufficient.

WARNING

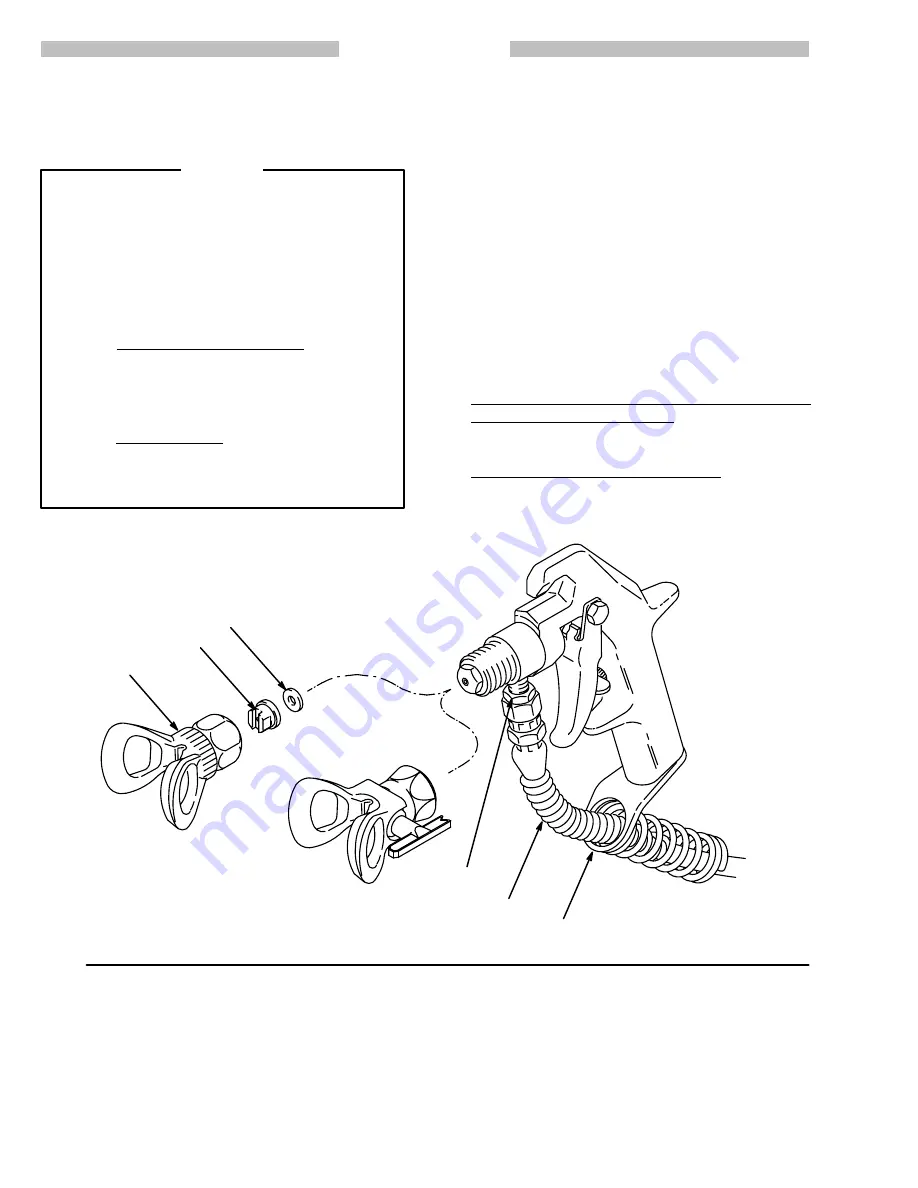

1.

Guide a grounded fluid hose (A) through the hose

guard (8), and connect the hose to the gun inlet

adapter (13).

2.

With no tip installed, start the pump or sprayer. Flush

it according to the instructions supplied with it.

3.

Strain the fluid you are spraying if it has particles that

could clog the spray tip. Prime the system with the

fluid you are spraying.

4.

Relieve pressure. See the procedure on page 2.

5.

Be sure the gun safety latch is engaged. See Fig 2.

Then install the tip and tip guard.

If you are using a Reverse-A-Clean

IV DripLess

Tip Guard and SwitchTip

, refer to manual

307–848, supplied, for detailed instructions.

If you are using a flat tip and tip guard, place the tip

and then the gasket (17) in the tip guard (16) and

screw the assembly tightly onto the gun nozzle.

Fig 1

16

13

8

A

0704

TIP

17