5

307–633

OPERATION

Fig 2

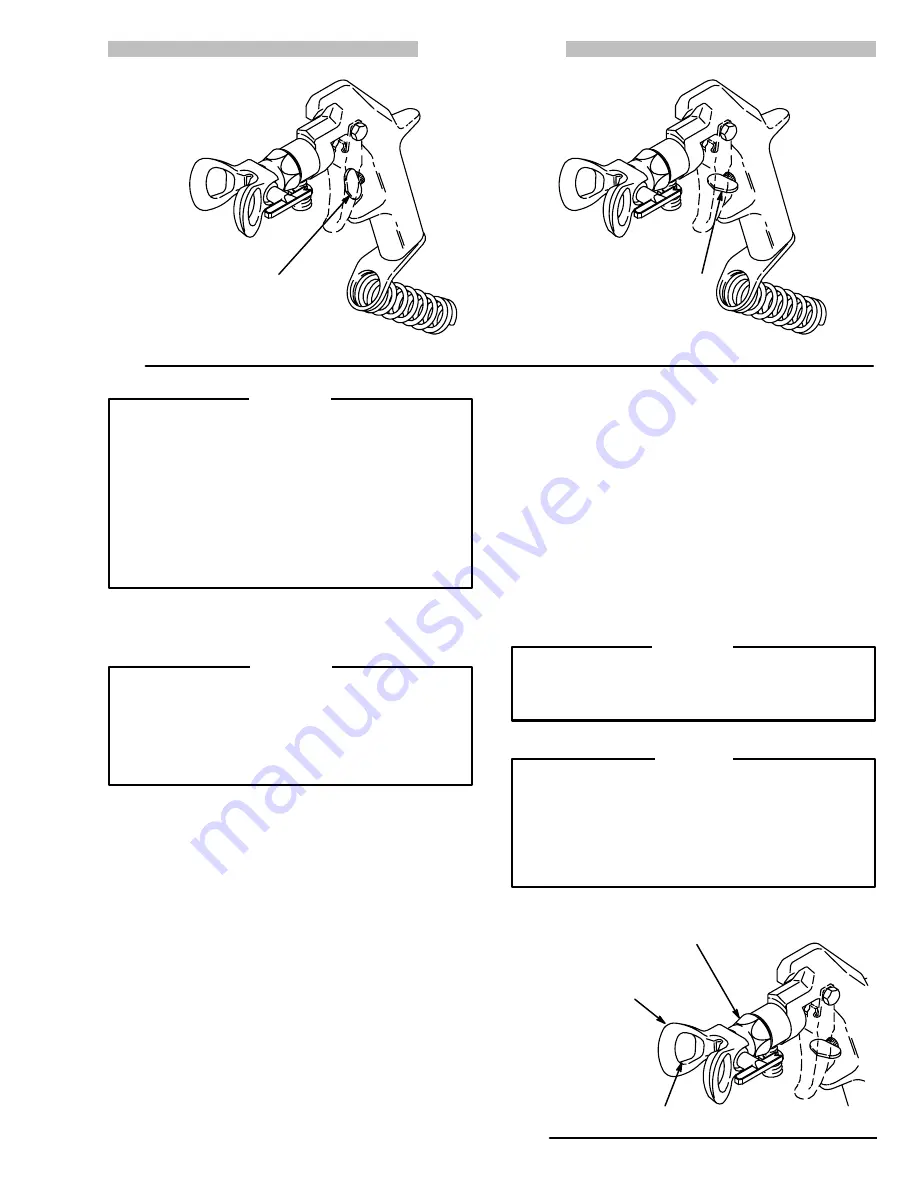

TO ENGAGE THE TRIGGER

SAFETY LATCH (ON SAFE),

TURN TO RIGHT ANGLE WITH

GUN BODY

TO DISENGAGE TRIGGER

SAFETY LATCH (OFF SAFE),

LIFT AND TURN LATCH

PARALLEL TO GUN BODY

0705

To reduce the risk of serious bodily injury, including

fluid injection or splashing in the eyes or on the

skin, always follow the Pressure Relief Proce-

dure on page 2 before checking, servicing, remov-

ing, changing or cleaning spray tips or any part of

the gun or system.

Whenever you stop spraying for a moment, en-

gage the gun safety latch. See Fig 2.

WARNING

WARNING

The wallet-sized warning card provided with this

gun should be kept with the operator at all times.

The card contains important treatment information

should an injection injury occur. Additional cards

are available from Graco Inc. at no charge.

1.

Start the pump. Adjust the fluid pressure so the spray

is completely atomized. Always use the lowest pres-

sure necessary to get the desired results. Higher

pressure may not improve the spray pattern and will

cause premature tip and pump wear.

2.

If adjusting the pressure does not give a good spray

pattern, try another tip size. Relieve pressure com-

pletely before changing tips.

3.

For maximum seat and needle life, Use a full-open,

full-close trigger action. Hold the gun about 14 in.

(350 mm) from and at right angles to the work sur-

face. Don’t swing the gun in an arc. Practice to find

the best length and speed of stroke.

Adjust the spray pattern

1.

To adjust the spray pattern direction, first relieve

pressure. Be sure the trigger safety latch is engaged.

Loosen the tip guard retaining nut. Turn the tip guard

so it is vertical for vertical pattern and horizontal for

a horizontal pattern. Tighten the retaining nut. See

Fig 3.

2.

The spray tip orifice size and spray angle determines

the coverage and size of pattern. When more cover-

age is needed, use a larger spray tip rather than in-

creasing the fluid pressure.

WARNING

To reduce the risk of a fluid injection injury, NEVER

use the gun with the tip guard or trigger safety

removed.

Openings in the tip guard are designed to reduce

paint buildup on the guard when spraying. Any

damage to the sharp edges of the openings causes

paint to collect at that area. To reduce the risk of

damage, never hang the gun by the tip guard. See

Fig 3.

CAUTION

Fig 3

TIP GUARD SHOWN

IN POSITION

FOR HORIZONTAL

PATTERN

RETAINING NUT

DO NOT DAMAGE

THESE EDGES

0706