7

307–633

SERVICE

WARNING

To reduce the risk of serious bodily injury, including

fluid injection, splashing in the eyes or on the skin,

always follow the Pressure Relief Procedure on

page 2 before adjusting, cleaning or repairing the

gun.

Periodically disassemble the gun to clean and inspect

parts. Clean all parts thoroughly, and check them careful-

ly for damage or wear. Replace parts as needed.

If the gun leaks at the tip when the trigger is released, the

needle or seat is worn or damaged and must be replaced.

See the procedure below. Repair Kit 218–143 is avail-

able. See page 11 to order.

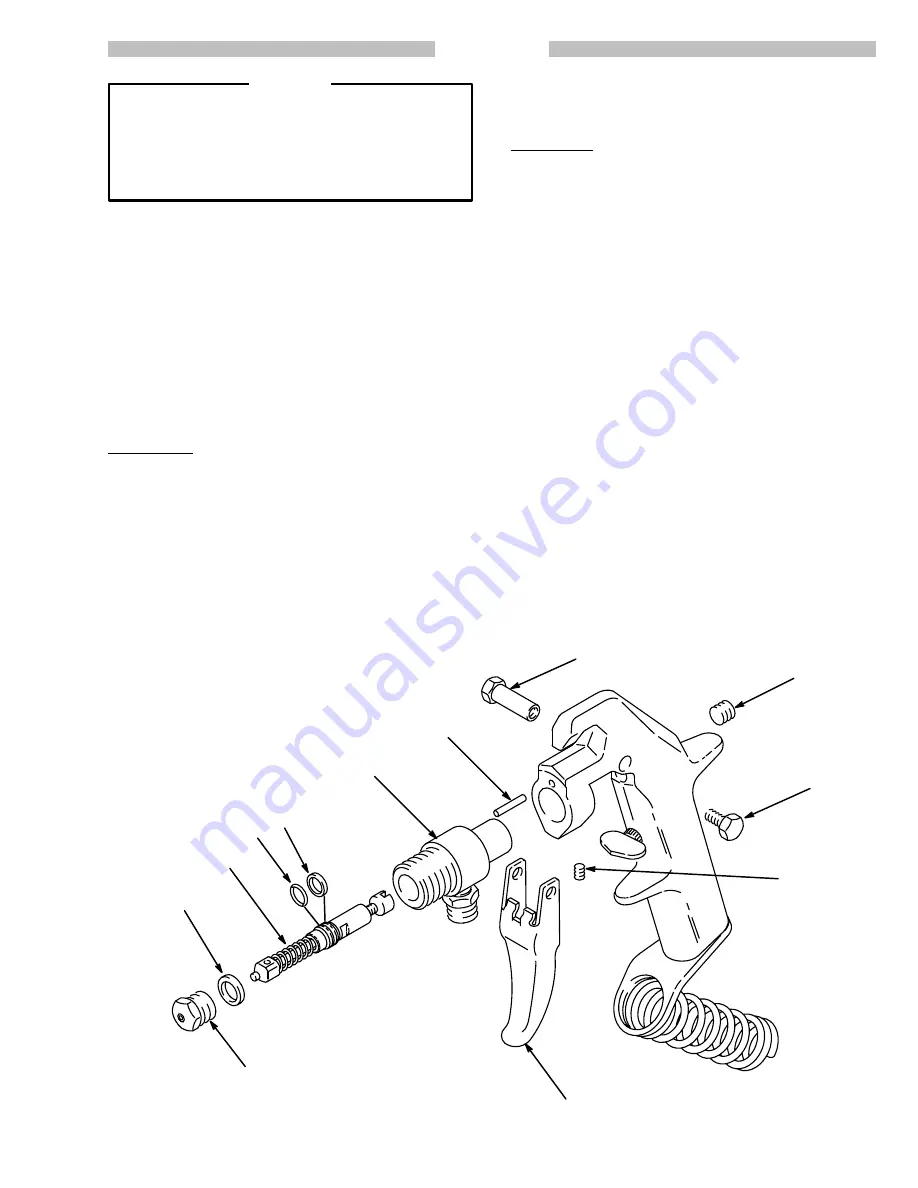

Needle replacement

See Fig 5.

Disassembly

1.

Relieve pressure.

2.

Disconnect the hose.

3.

Remove the tip guard, spray tip and gasket.

4.

Remove the trigger (10), plug (3), diffuser–seat (15),

gasket (14) and setscrew (12). Pull the housing (19)

off the gun body.

5.

Gently tap the needle (18) from the rear of the hous-

ing (19) to push it out the front.

Reassembly

1.

Lubricate the o–ring (D) and backup ring (E) of the

new needle assembly (18**) with lightweight oil.

2.

Insert the rear of the needle (18) through the front of

the housing (19). Grasp the rear of the needle and

pull it

STRAIGHT BACK until the rings (D,E) seat in

the housing.

3.

Using the pin (20) for alignment, push the housing

(19) onto the gun body. Install the setscrew (12) and

torque it to 30–40 in–lb (3.4–4.5 N.m).

4.

Install the trigger (10).

5.

Put the new gasket (14) on the diffuser-seat (15).

6.

While squeezing the trigger, screw the diffuser–seat

into the fluid housing (19). Release the trigger.

Finish tightening the diffuser-seat to 20–25 ft–lb

(27–34 N.m).

7.

DO NOT install the plug (3) yet!

8.

Adjust the needle before operating the gun. See

page 8.

15**

**14

**18

2

3

1

10

TORQUE TO

20–25 ft–lb

(27–34 N.m)

12

TORQUE TO

30–40 in–lb

(3.4–4.5 N.m)

D

E

19

20