Operation

12

311052E

Operation

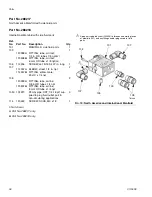

Pressure Relief Procedure

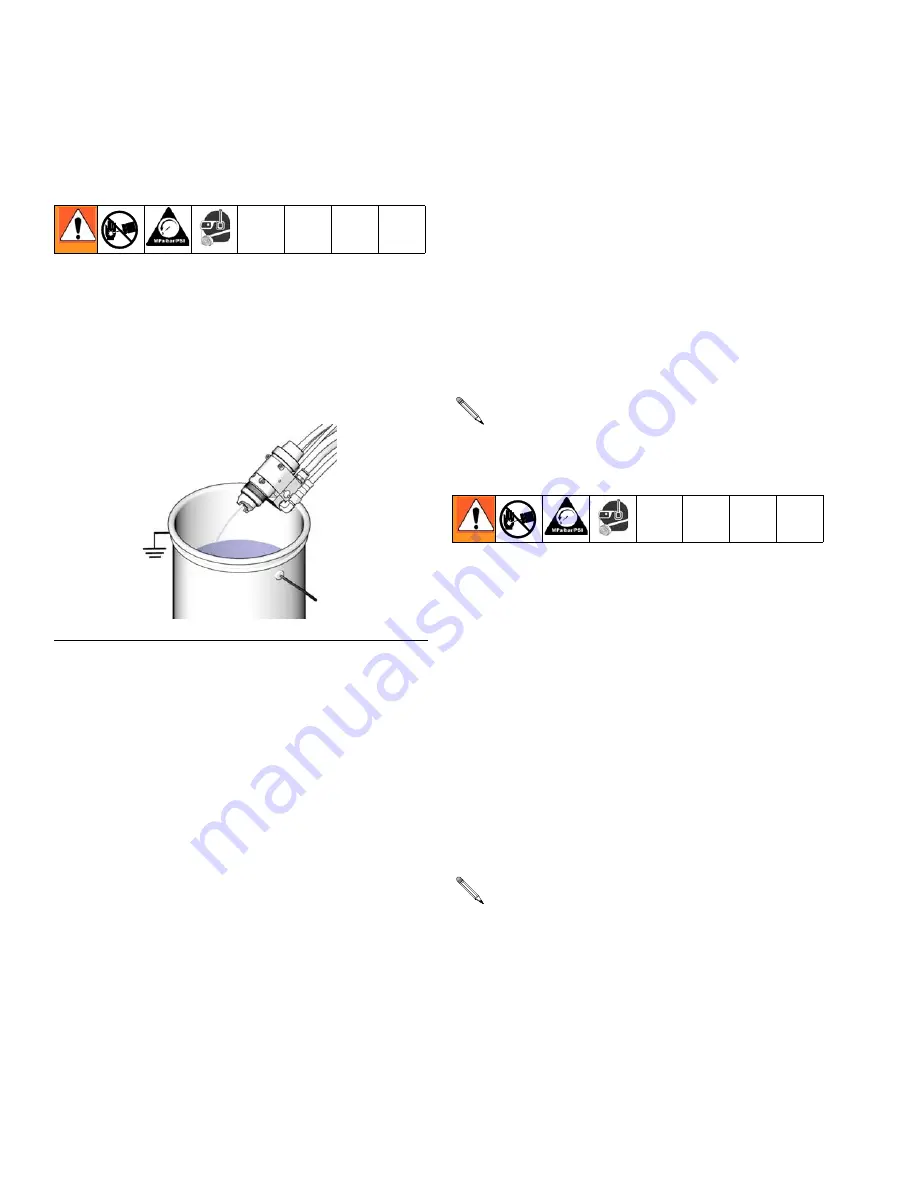

1.

Turn off the air and fluid supply to the gun.

2.

Close the bleed-type master air valve (required in

the system).

3.

Trigger the gun into a grounded metal waste con-

tainer to relieve the fluid pressure.

4.

Open the pump drain valve (required in the system)

to relieve fluid pressure in the displacement pump.

In addition, open the drain valve connected to the

fluid pressure gauge (in a system with fluid regula-

tion) to relieve fluid pressure in the hose and gun.

Have a container ready to catch the drainage.

5.

Leave the drain valve(s) open until you are ready to

spray again.

6.

If you suspect that the spray tip or hose is com-

pletely clogged or that pressure has not been fully

relieved, very slowly loosen the hose end coupling

and relieve pressure gradually, then loosen the cou-

pling completely. Clear the tip or hose obstruction.

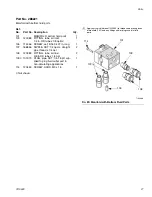

Adjust Spray Pattern

The air-assisted spray gun combines airless and air

spray concepts. The spray tip shapes the fluid into a fan

pattern, as does a conventional airless spray tip. Air

from the air cap further atomizes the fluid and completes

the atomization of the paint tails into the pattern to pro-

duce a more uniform pattern.

The fan air can be used if necessary to slightly adjust

the pattern size.

1.

Set the fluid pressure at 300 psi (2.1 MPa, 21 bar)

with the fluid regulator.

2.

Trigger the gun to check the atomization; do not be

concerned about the pattern shape yet.

3.

Slowly Increase the fluid pressure just to the point

where a further increase in fluid pressure does not

significantly improve fluid atomization.

4.

Turn on the atomizing air and set the air pressure at

about 10 psi (70 kPa, 0.7 bar). Check the spray pat-

tern, and then adjust the air pressure until the tails

are completely atomized and pulled into the spray

pattern. See F

IG

. 11. Do not exceed 100 psi (0.7

MPa, 7 bar) air pressure to the gun.

For a narrower pattern, supply air to the gun fan air inlet

(or open the fan adjustment valve on manifold 288223).

The tip size is the primary controller of the pattern size.

Use the fan air only as needed to slightly adjust the pat-

tern size.

F

IG

. 10: Pressure Relief

TI8174a

Air-assisted spray guns differ from air spray guns in

that increasing the fan air reduces the pattern

width. To increase the pattern width, use less fan

air or a larger size tip.

For HVLP operation do not exceed 10 psi at the air

cap. Use HVLP verification kit 249140 to measure

the atomization pressure at the air cap.

Summary of Contents for G40

Page 30: ...Notes 30 311052E Notes ...