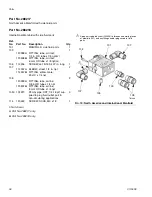

Maintenance

311052E

15

General System Maintenance

1.

Perform Pressure Relief Procedure, page 12.

2.

Clean the fluid and air line filters daily.

3.

Check for any fluid leakage from the gun and fluid

hoses. Tighten fittings or replace equipment as

needed.

4.

Flush the gun before changing colors and whenever

you are done operating the gun.

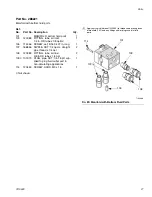

Flushing and Cleaning

1.

Perform Pressure Relief Procedure, page 12.

2.

Shut off the gun fan and atomizing air.

3.

Remove the air cap retaining ring (8), air cap (30),

and spray tip (9).

4.

Disconnect the fluid supply hose and air supply

hose from the gun.

5.

Connect the solvent supply hose to the gun.

6.

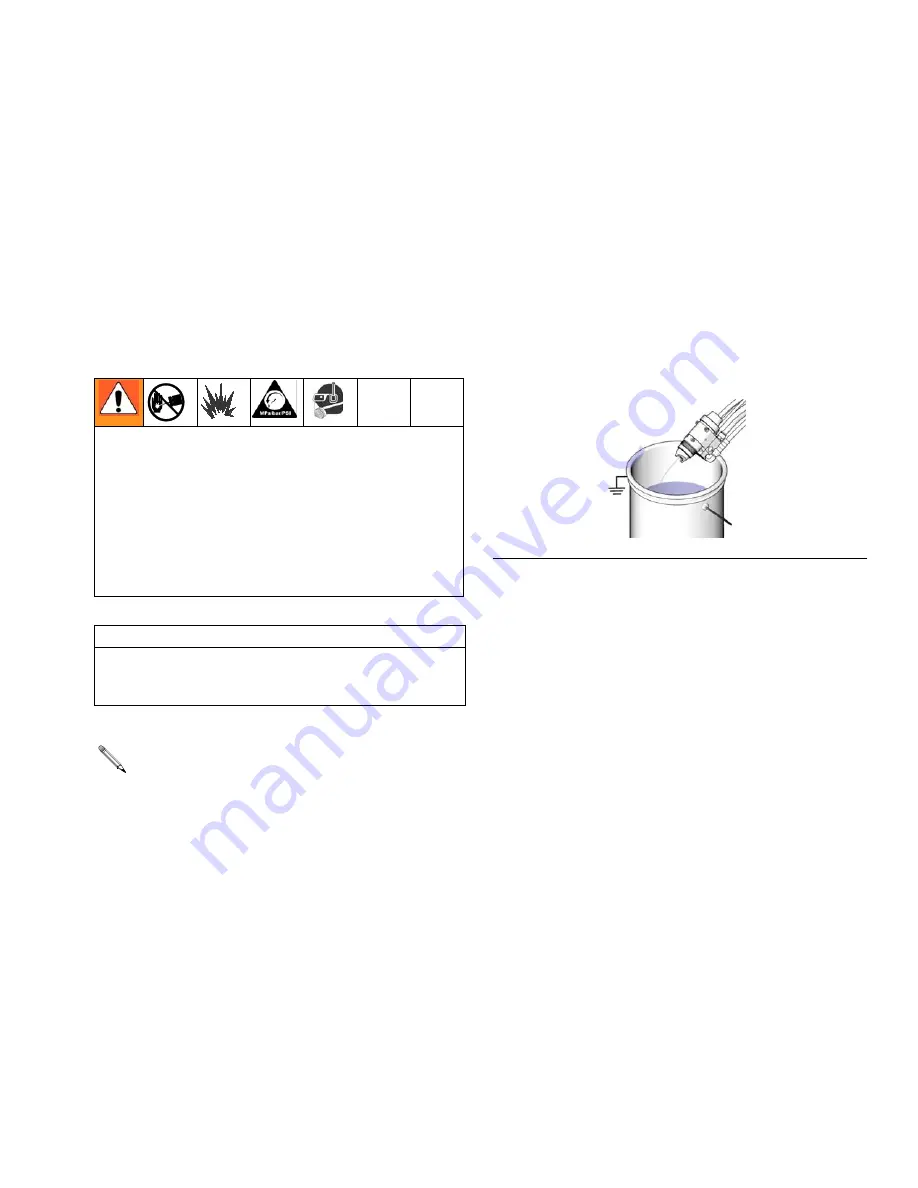

Increase the pressure slowly. Point the gun down

into a grounded metal container, and flush the gun

with solvent until all traces of fluid are removed from

the gun passages.

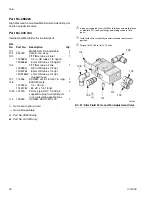

To reduce the risk of serious injury, including splash-

ing fluid in the eyes or on the skin, or static electric

discharge when flushing:

•

Ensure that the entire system, including flushing

pails, are properly grounded.

•

Remove the spray tip.

•

Maintain metal to metal contact between the gun

and the flushing pail.

•

Use the lowest possible pressure.

CAUTION

This gun is not adjustable. To ensure proper shutoff,

screw the piston cap (27) onto the housing (1) until it

bottoms out.

•

Flush before changing colors, before fluid can

dry in the equipment, at the end of the day,

before storing, and before repairing equipment.

•

Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

•

Flush with a fluid that is compatible with the

fluid being dispensed and the equipment wetted

parts.

•

If it is available, the flushing procedure provided

in the pump or sprayer manual should be used

instead of this procedure.

•

Clean the front of the tip frequently during the

day to reduce buildup.

F

IG

. 13

TI8174a

Summary of Contents for G40

Page 30: ...Notes 30 311052E Notes ...