4

308660

Pinion, Clutch, Clamp, Field, & Engine

If servicing clutch components only, see Manual

308620.

If no service is needed for internal parts of pinion

housing, remove drive assembly (drive and pinion

housing) from clutch housing. See Manual 308620.

Pinion Housing Removal

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 8.

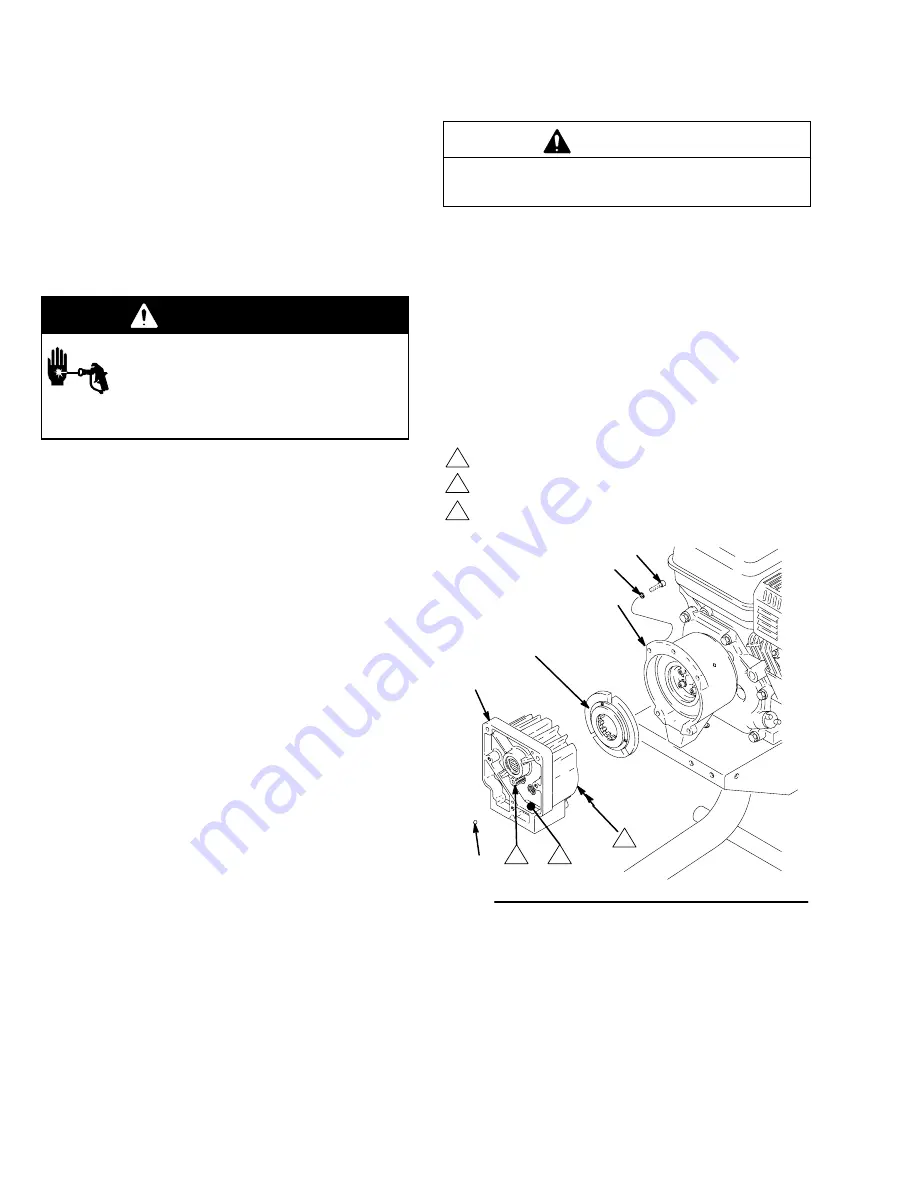

NOTE:

Refer to Fig. 4 for Steps 1 to 5.

1.

Follow the

Pressure Relief Procedure

, page 8.

2.

If the drive housing has not yet been removed,

follow steps 1 through 6 of

DRIVE HOUSING

, on

page 1.

3.

Remove the two bottom screws (59) and lock-

washers (16) first, then remove the top three

screws (59) and lockwashers (16).

4.

Pull the pinion housing (2) away from the clutch

housing (1). The armature (51b) will come with it.

5.

Pull the armature (51b) off the hub (2h**

)

of the

pinion housing. Also see Fig. 5.

6.

If replacing the complete pinion housing assembly

(2), brush bearing grease (supplied) on the pinion

shaft teeth. Then recoat the pinion shaft teeth with

bearing grease (supplied). Pack the remaining

bearing grease in the bottom part of the pinion

housing. Use 1/4 tube of the bearing grease.

7.

Install new gasket (64) (supplied).

8.

Reassemble to drive housing.

CAUTION

Do not lose the thrust ball (2d). Refer to the

CAU-

TION

on page 1 for more information

NOTE:

To disassemble the pinion, go to page 5. To

disassemble more of the sprayer, see Manual 308620.

To reassemble the sprayer from this point, skip ahead

to

Reassembly

, page 6, Step 1.

05836A

Fig. 4

59

16

1

51b

2

See page 5.

1

1

2

2

Brush with bearing grease

3

Pack with bearing grease (1/4 tube).

3

2d