6

308660

Reassembly

NOTE:

With the autogap style armature, the gap be-

tween the rotor and the armature is critical for proper

operation. The clutch kits with an autogap style arma-

ture include a cardboard spacer (p/n 186–857) to set

the proper gap. This spacer is for use

only

during

installation.

1.

Clean the face of the

armature (51b)

. With the flat

side of the armature facing the rotor (51a), slide

the armature onto the hub (2h) in the drive/pinion

assembly (D) just until the chamfered end of the

hub (2h) protrudes through the armature. See

Detail B, Fig. 7. There will be significant resis-

tance. Attach the cardboard spacer, supplied with

the clutch kit, to the face of the armature. Engage

the tabs on the spacer with the slots in the arma-

ture or bend tabs over outside diameter of arma-

ture.

Brace the cart against a wall to keep it from rolling.

Push the drive/pinion assembly onto the clutch

housing (1). There will be significant resistance.

When the mating surfaces of the drive/pinion as-

sembly and the clutch housing (1) are flush, re-

move the drive/pinion assembly.

Remove the

cardboard spacer.

2.

Assemble the

drive assembly (D)

to the clutch

housing (1), using the capscrews (59) and lock-

washers (16). See Fig. 7.

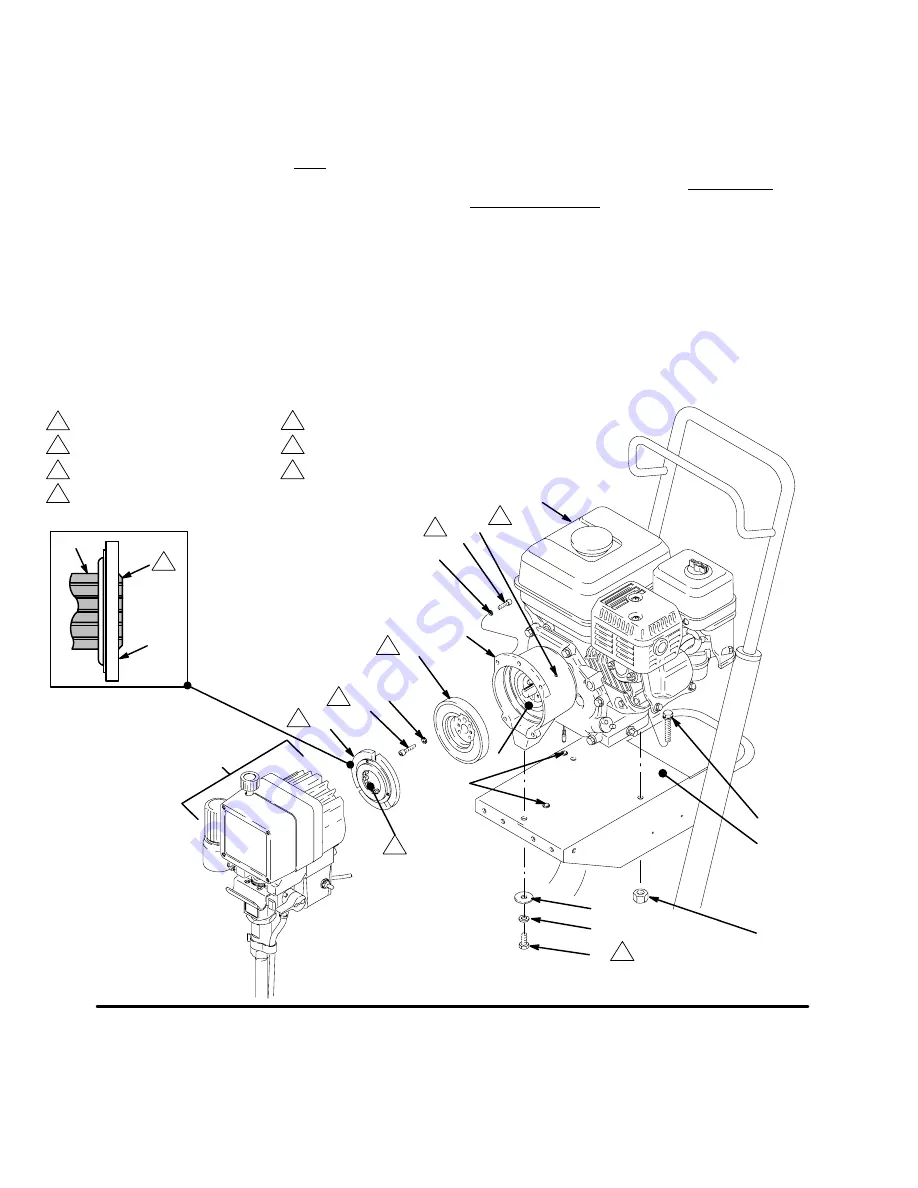

05843A

Fig. 7

A

78

61

51b

16

51a

53

1

48

57

62

58

77

16

59

1

3

4

2

Torque the screw to 7 ft–lb (9.5 N.m).

The face must be clean.

1

2

Spline

4

2

To engine alternator.

Detail B

5

52

2h

D

60

50

Chamfered end of hub (2h)

5

06007

6

Apply low strength thread locker.

7

Torque to 100 in.-lb (N

m).

7

6

6