Operation

333011D

17

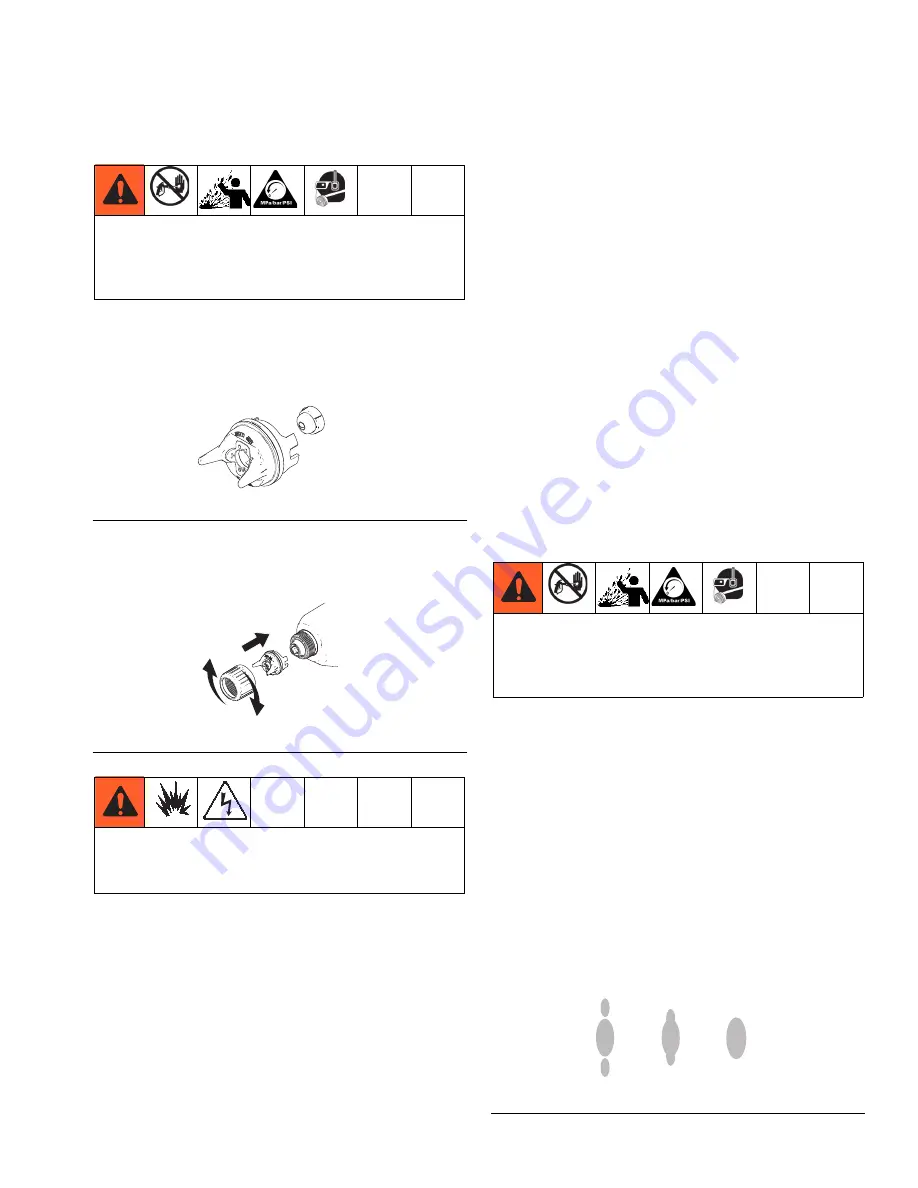

Install the Spray Tip

1. Relieve the pressure. Follow

Pressure Relief Pro-

cedure

, page 16.

2. Align the spray tip tab with the groove in the air cap.

Install the tip.

3. Install the air cap and retaining ring. Orientate the

air cap and tighten the retaining ring securely. Be

careful not to damage the electrode.

Set the Atomization Fluid

Pressure

See F

IGURE

5.

Atomization fluid pressure will vary based on the viscos-

ity of the fluid, flow rate desired, and other system char-

acteristics.

1. Turn off the turbine air (TA), atomization air (A1),

and fan air (A2).

2. Start the pump. Set the fluid regulator to 400 psi (2.8

MPa, 28 bar).

3. With the turbine air (TA), atomization air (A1), and

fan air (A2) turned off, spray a test pattern, holding

the gun 12 in. (305 mm) from the surface. Examine

the particle size. Do not be concerned about the

presence of tails; they will be removed in step 6.

4. Increase the fluid pressure in small increments.

Spray another pattern and compare the particle

size. Smaller particle size indicates improved atomi-

zation.

5. Continue to increase the fluid pressure and spray

test patterns. Do not exceed 3000 psi (21 MPa, 210

bar) fluid pressure. When the particle size remains

constant, the fluid is being atomized at the lowest

possible fluid pressure.

For improved atomization at lower fluid flow rates,

change to a smaller tip orifice size.

6. Turn on the atomization air (A1) and adjust the air

pressure until the tails disappear.

See

Spray Pattern Troubleshooting

on page 24 to

correct spray pattern problems.

7. The pattern width can also be reduced by applying

fan air pressure (A2).

To reduce the risk of skin injection and splashing,

follow the

Pressure Relief Procedure

before

removing or installing the spray tip or air cap/tip

guard.

F

IG

. 10 Spray Tip Alignment

F

IG

. 11 Install Air Cap Assembly

To reduce the risk of fire, explosion, or electric

shock, never operate the gun with a damaged

electrode.

WLD

WLD

To reduce the risk of injury, never exceed the

maximum working pressure on the lowest rated

system component. Maximum working pressure of

this equipment is

3000 psi (21 MPa, 210 bar)

.

F

IG

. 12 Eliminating Tails

No Air

Too Little Air

Correct

Amount of Air