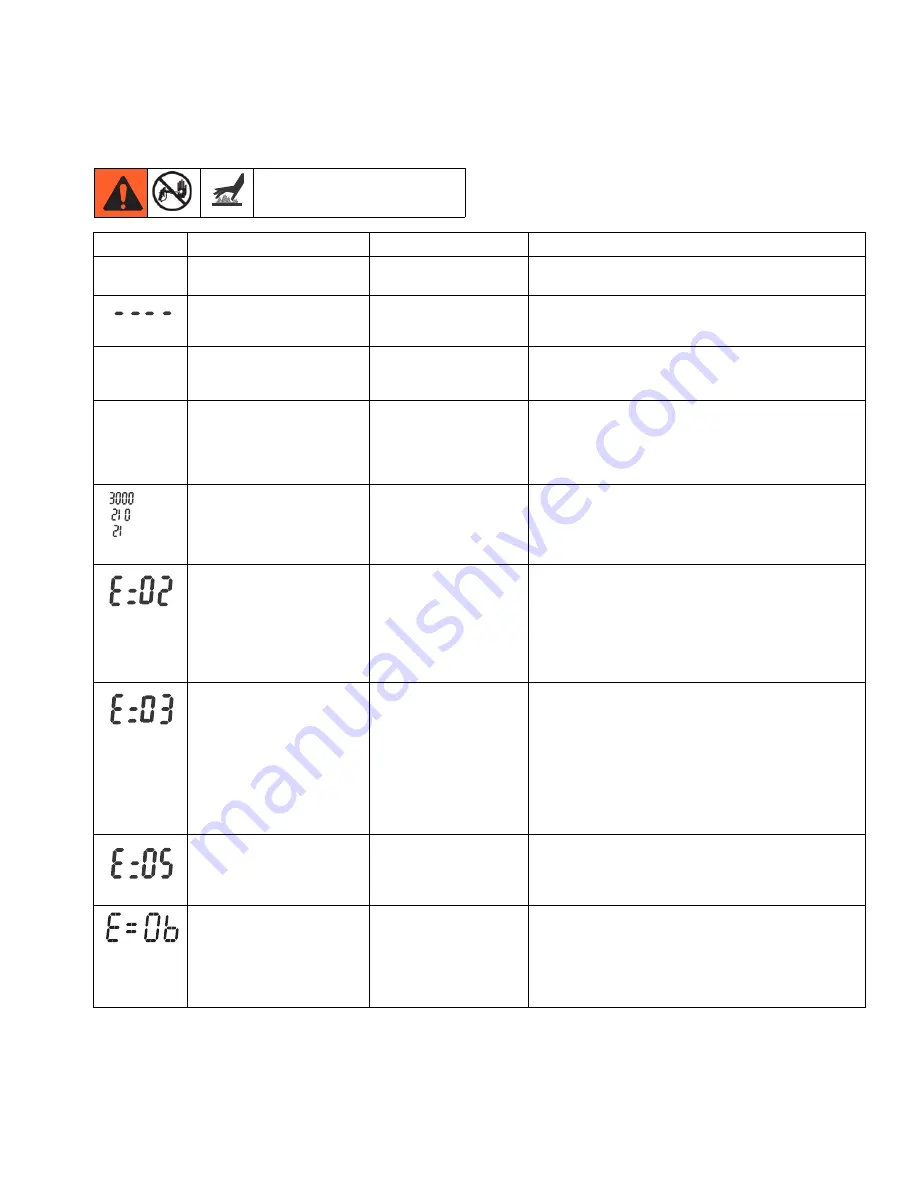

Digital Display Messages

313888E

23

Digital Display Messages

* Error codes also appear on control board as a blinking red

LED. LED is an alternate to digital messages.

1

Remove two screws (71) and swing down cover (130).

2

Start engine. Blink count is the same as error code(E=0X).

After a fault, follow these steps to restart sprayer:

1

Correct fault condition.

2

Turn sprayer OFF.

3

Turn sprayer ON.

(E02 and E06 errors will self-correct when system is reduced)

DISPLAY*

SPRAYER OPERATION

INDICATION

ACTION

No Display

Sprayer may be

pressurized

Loss of power or

display not connected

Check power source. Relieve pressure before repair

or disassembly. Verify display is connected.

Sprayer may be

pressurized

Pressure less than

60 psi (4 bar, 0.4 MPa)

Increase pressure as needed

BASE

or

TOP

Displays installed pump

when engine is started

Normal operation

Spray

OFF

FLOW 1

FLOW 2

or

FLOW 3

Displays flow control

setting in Base Coat mode

when pump control setting

is changed

Normal operation

(with Base Coat pump)

Spray

Sprayer is pressurized.

Power is applied. (Pressure

varies with tip size and

pressure control setting.)

Normal operation

Spray

Top Coat Only:

Sprayer

stops. Engine is running.

Pressure greater than

4500 psi (310 bar, 31

MPa)

1

Check fluid path for clogs.

2

Use Graco paint hose, 3/8 in. x 50 ft minimum.

Smaller hose or metal braid hose may result in

pressure spikes.

3

Replace transducer if fluid path is not clogged and

proper hose is used.

Sprayer stops. Engine is

running.

Pressure transducer

faulty, bad connection

or broken wire

1

Check transducer connection.

2

Disconnect and reconnect transducer plug to

ensure good connection with control board

socket.

3

Open prime valve. Replace sprayer transducer

with known good transducer and run sprayer.

Replace transducer if sprayer runs or control

board if sprayer does not run.

Sprayer stops. Engine is

running.

High clutch current

1

Check wiring connections.

2

Measure: 1.7 + 0.2

Ω

across clutch field at 70°F.

3

Replace clutch field assembly.

Base Coat Only:

Sprayer

stops. Engine is running.

Pressure greater than

1000 psi (69 bar, 6.9

MPa)

1

Open prime valve and gun.

2

Verify no flow obstructions. Use Graco texture

hoses 3/4 in. x 50 ft minimum.

3

Replace transducer if fluid path is not clogged and

proper hose is used.

ti6314a

psi

bar

MPa

ti6315a

ti6316a

ti6317a

ti6318a

Summary of Contents for HTX 2030

Page 26: ...Notes 26 313888E Notes ...

Page 27: ...Notes 313888E 27 Notes ...