Table of Contents

Warnings

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

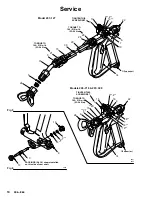

Service

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

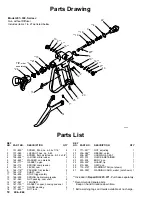

Model 206–718

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 207–300

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 207–127

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extension Kit 207–049

14

. . . . . . . . . . . . . . . . . . . . . . . . .

Accessories

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty and Disclaimers

16

. . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

his symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

If there is any static sparking or you feel an electric shock while using this equipment, stop

spraying immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not operate a gasoline engine in the spray area.

Ground the equipment and the object being sprayed. See Grounding on page 5.

WARNING

WARNING