21

309378

Troubleshooting

WARNING/MISE EN GARDE/ADVERTENCIA/ADVERTÊNCIA

INJECTION HAZARD/DANGERS D’INJECTION/PELIGRO DE INYECCIÓN/PERIGO DE INJECÇÃO

To reduce risk of serious injury, whenever instructed to relieve pressure, do steps 1. – 3.; page 17.

Pour réduire le risque de blessure grave lors de chaque décompression, procéder aux opération

1 à 3 de la page 17.

Con el fin de reducir los riesgos de heridas graves cuando tenga que liberar la presión, lleve a cabo

los pasos 1. – 3.; página 17.

Para reduzir o risco de ferimentos graves sempre que for instruído para efectuar a descompressão,

siga os passos 1. – 3.; página 17.

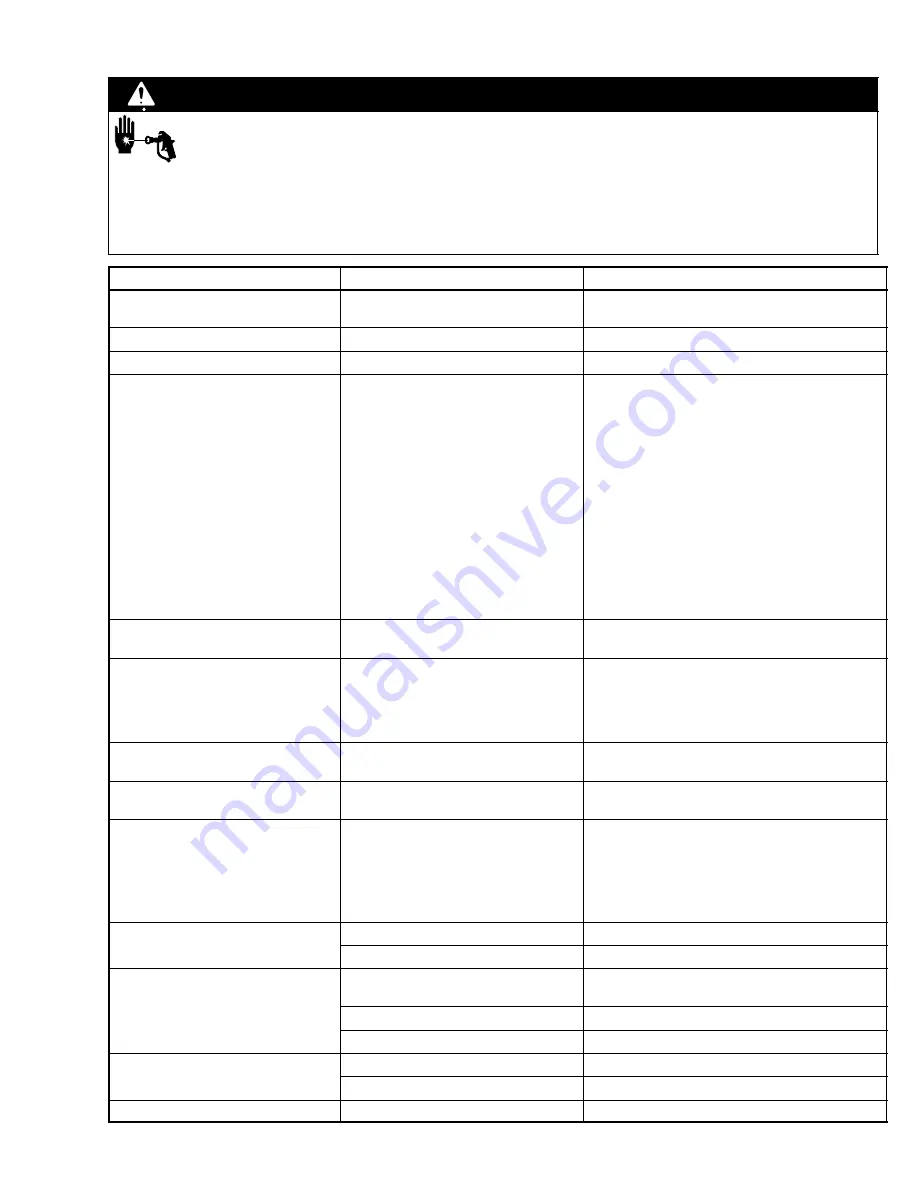

PROBLEM

CAUSE

SOLUTION

Gas engine pulls hard (won’t start)

Hydraulic pressure is too high

Turn hydraulic pressure knob counterclockwise

to lowest setting

Gas engine will not start

Switch OFF, low oil, no gasoline

Consult engine manual, supplied

Gas engine doesn’t work properly

Consult engine manual, supplied

Gas engine operates, but

displacement pump doesn’t operate

Pump switch is OFF

Set pump switch ON

Pressure setting too low

Increase pressure, page 10

Displacement pump outlet filter

(if used) is dirty or clogged

Clean the filter

Tip or tip filter (if used) is clogged

Remove tip and/or filter and clean

Hydraulic fluid too low

Shut off sprayer and add fluid immediately*. See

page 8.

Hydraulic pump worn or damaged

Bring sprayer to Graco distributor for repair

Displacement pump rod seized by

dried paint

Service pump. See manual 309277.

Directional valve not shifting

Set pump switch OFF, then ON. Manual 309379.

Displacement pump operates, but

output is low on upstroke

Piston ball check not seating properly.

Piston packings worn or damaged.

Service piston ball check. See manual 309277.

Replace packings. See manual 309277.

Displacement pump operates but

output is low on downstroke and/or

on both strokes

Piston packings worn or damaged.

Intake valve ball check not seating

properly.

Suction tube air leak

Remove clip and retighten or replace packings.

See manual 309277.

Service intake valve ball check. See manual

309277.

Tighten suction tube

Paint leaks and runs over side of

wetcup

Loose wet–cup

Throat packings worn or damaged

Tighten just enough to stop leakage

Replace packings. See manual 309277

Excessive leakage around hydraulic

motor piston rod wiper

Piston rod seal worn or damaged

Replace these parts. See manual 309379

Fluid delivery is low

Pressure setting too low

Displacement pump outlet filter

(if used) is dirty or clogged

Intake line to pump inlet is not tight

Hydraulic motor is worn or damaged

Large pressure drop in fluid hose

Increase pressure, page 10

Clean filter

Tighten

Bring sprayer to Graco distributor for repair

Use larger diameter hose

The sprayer overheats

Cooler is damaged

Replace

Oil level is low

Fill with oil. See page 8.

Spitting from gun

Air in fluid pump or hose

Check for loose connections on siphon

assembly, tighten, then reprime pump

Loose intake suction

Tighten

Fluid supply is low or empty

Refill supply container

DTS does not display

Loose wiring

Remove cover and correct poor connections

Bad LCD or board

Bring sprayer to Graco distributor for repair

DTS displays error codes

Various over-pressure conditions

Page 25