Prepare

Prepare

Prepare the

the

the Isolation

Isolation

Isolation Valve

Valve

Valve Before

Before

Before the

the

the First

First

First

Use

Use

Use

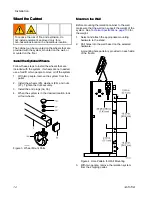

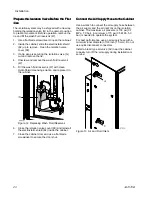

The isolation system may be shipped with a tie wrap

holding the isolation valve (G) in the upmost position

to prevent movement. Before operation, remove the

tie and fill the wash fluid reservoir (W).

1.

Use a flat blade screwdriver to open the cabinet.

2.

Inside the cabinet, slide the electrostatic shield

(82) up to remove. Open the isolation valve

cover (99).

3.

If a tie wrap is securing the isolation valve (G),

cut and remove the tie.

4.

Unscrew and remove the wash fluid reservoir

(W).

5.

Fill the wash fluid reservoir (W) with clean

HydroShield cleansing solution and replace it in

the cabinet.

Figure 12 Replacing Wash Fluid Reservoir

6.

Close the isolation valve cover (99) and reinstall

the electrostatic shield (82) inside the cabinet.

7.

Close the cabinet door and use a flat blade

screwdriver to secure the door shut.

Connect

Connect

Connect the

the

the Air

Air

Air Supply

Supply

Supply Hose

Hose

Hose to

to

to the

the

the Cabinet

Cabinet

Cabinet

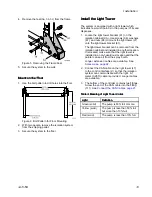

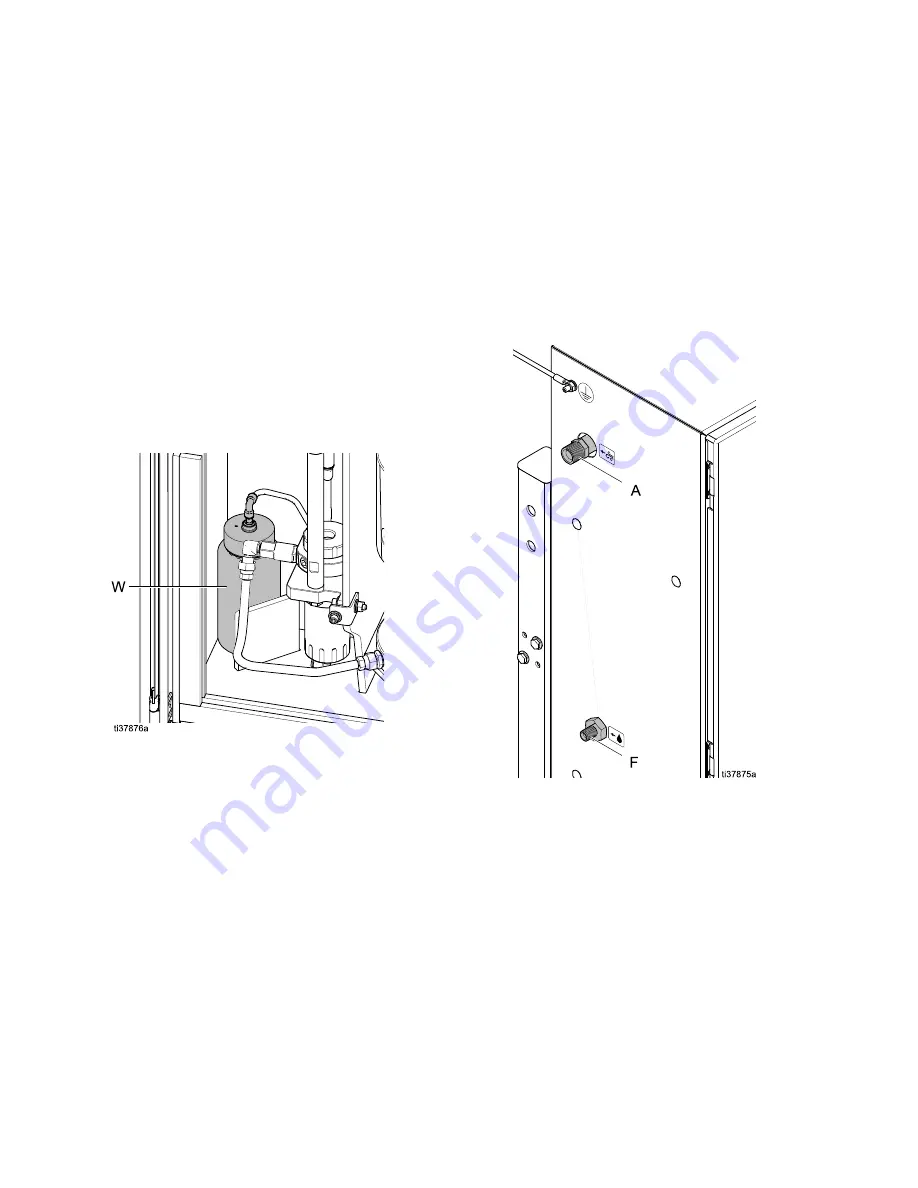

Use a wrench to connect the air supply hose between

the air supply and the air inlet (A) on the isolation

cabinet. The maximum air pressure is 100 psi (0.7

MPa, 7.0 bar). A minimum of 70 psi (0.5 MPa, 5.0

bar) is needed to operate the system.

For best performance use an air supply hose with a

minimum inner diameter of 3/8 inch (10 mm). Do not

use quick disconnect connectors.

Install a bleed type air valve (AV) near the cabinet

to easily turn off the air supply during installation or

service.

Figure 13 Air and Fluid Inlets

20

3A7370B