10. To remove and replace the wiper seal (306):

a.

Inside the middle housing (307) on the fluid

side, remove the wiper seal (306). Use pliers

to grip the seal and pull it out.

b.

When replacing the wiper seal (306), make

sure that it is inserted on the fluid side of the

middle housing (307). The diameter of the

fluid side is slightly smaller than the air side

of the housing.

c.

Apply grease to the wiper seal (306) and

snap it into the groove in the middle housing

(307).

Figure 39 Middle Housing Parts

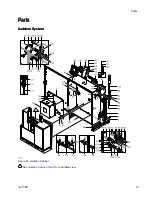

Reassemble

Reassemble

Reassemble the

the

the Pump

Pump

Pump

1.

Lay the pump on its side.

2.

Grease the wiper seal (306) in the middle

housing (307).

3.

With the non-sensor end, push the piston rod

(305) through the housing (307). The end must

go through the air side of the housing. (The air

side has the larger diameter.)

4.

Assemble the air piston (316):

a.

Place the o-ring (317) around the air piston

(316) and then grease the o-ring.

b.

Screw the air piston (316) onto the piston rod

(305). Tighten with a wrench on the flats of

the piston rod (305) and a wrench on the flats

of the air piston (316).

c.

When tightened adequately, the white of

the piston rod (305) and the magnet sensor

(314), should protrude slightly from the air

piston (316).

5.

Assemble the fluid piston (301):

a.

Snap the U-cup seal (302) into place on the

fluid piston (301) and then grease the outside

of the U-cup seal.

b.

Screw the fluid piston (301) onto piston rod

(305). Tighten with a wrench on the flats of

the piston rod (305) and wrench on the flats

of the fluid piston (301).

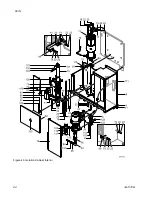

6.

Grease the inside of the air cylinder (319) and

then wiggle it into place over the air piston (316)

and into the middle housing (307).

7.

Push the air piston (316) into the middle housing

(307) so that the fluid piston (301) extends out

of the middle housing.

8.

Grease the inside of the fluid cylinder (310) and

then place either end over the fluid piston (301).

Push it into place into the middle housing (307).

9.

With the fluid cylinder (310) up, orient the pump

so that you are facing the two weep holes in the

middle housing (307). The holes indicate the

front of the system in the isolation cabinet.

10. Place the o-ring (309) onto the fluid cylinder

(310).

11. Place the fluid cover (311) onto the fluid cylinder

(310) so that the holes for the fittings line up with

the weep holes in the middle housing (307).

12. Spin the tie rod screws (312), lock washer (304),

and plain washer (322) into the fluid cover (311).

Tighten in a cross pattern only until snug.

13. Lay the pump on its side to tighten the tie rod

screws (312) in a cross pattern. Torque to 160

in-lb (18 N•m). Tighten the tie rod screws twice

because the plastic pieces relax.

3A7370B

73