Maintenance

Maintenance

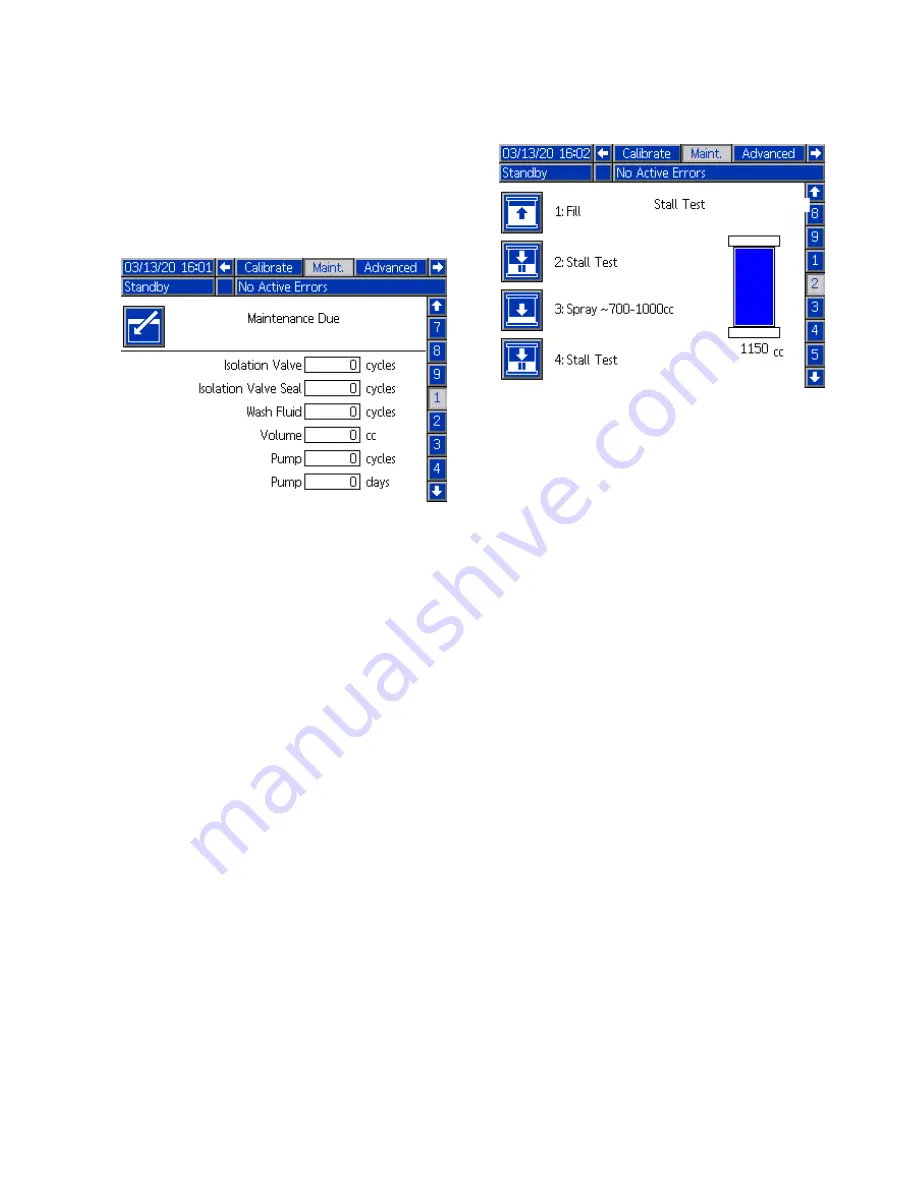

Maintenance Screens

Screens

Screens

Maintenance

Maintenance

Maintenance 1:

1:

1: Maintenance

Maintenance

Maintenance Due

Due

Due

Use the Maintenance Due screen to set maintenance

reminders for system components. When the cycle

counters for each item reach these set values, an

advisory is displayed on the screen.

Isolation

Isolation

Isolation Valve:

Valve:

Valve: The number of times the isolation

valve shuttle has moved.

Isolation

Isolation

Isolation Valve

Valve

Valve Seal:

Seal:

Seal: The number of times the seals

in the housing have been engaged.

Wash

Wash

Wash Fluid:

Fluid:

Fluid: The number of times the wash fluid has

been moved through the isolation valve.

Volume:

Volume:

Volume: The total volume (cc) of fluid dispensed by

the pump between maintenance events. This value

does not account for material that is pushed through

the system in Prime mode.

Pump:

Pump:

Pump: The number of times the pump has dispensed

fluid.

Pump:

Pump:

Pump: The number of days that have passed since

the counter was reset.

Maintenance

Maintenance

Maintenance 2:

2:

2: Pump

Pump

Pump Stall

Stall

Stall Test

Test

Test

Use the Pump Stall Test screen to test the fluid pump

for internal and external fluid leaks. During the Pump

Stall Test, the pump position is held for 60 seconds

while the system looks for leaks.

Before calibrating the pump, be sure that air and fluid

are supplied to the system.

Prime the system to make sure that there is no air in

the pump. Put the system into Standby mode.

1.

Press the Fill button. The system will

automatically fill.

Be sure the gun trigger is released. During the

test the fluid line will be pressurized to the active

preset value. No air will be sent to the gun.

2.

Press the Stall Test button. The pump will

pressurize and the system will monitor the linear

sensor to look for leaks with the pump at the top

if the pump stroke. The screen will display the

text, "Stall Test" and "Test In Progress."

The test takes about 1 minute. If the test is

successful, a confirmation displays on the

screen. The system will return to Standby.

3.

Press the Spray button. Dispense between

700-1000 cc so that the pump is about 1/4 full.

4.

Be sure the gun trigger is released and press

the Stall Test button. The system will now be

tested with the pump near the bottom of the

pump stroke.

The test takes about 1 minute. If the test is

successful, a confirmation displays on the

screen. The system will return to Standby.

Note

In addition to the HydroShield, this test

checks the hose connections and gun. If

the test fails it should be repeated with the

ball valve on the inlet to the fluid pressure

regulator in the closed position. Then the test

will only check the pump and connections

inside the HydroShield.

3A7370B

45