Operation

8

334625B

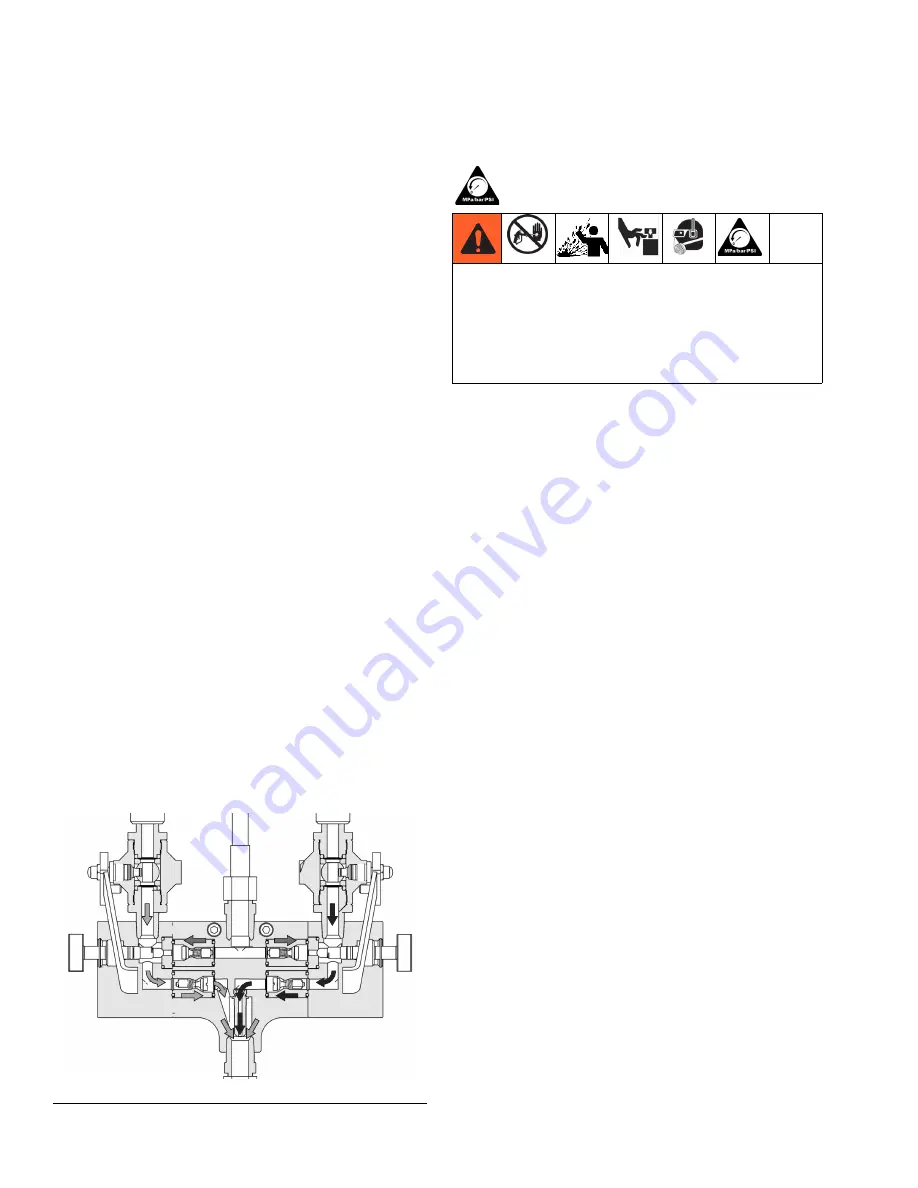

Manifold Functional Operation

See F

Spray Position

•

Common handle down “Spray Position”

•

Solvent flush “A” closed

•

“Solvent flush “B” closed

A and B material flows through A and B valves into mix-

ing chamber. A and B stay separate until exiting the mix

chamber.

Flush “B” Position

•

Common handle up “Stand-by Position”

•

Solvent flush “A” closed

•

“Solvent flush “B” open

Solvent flows through the solvent flush “B” check into

catalyst fluid passage. Then through catalyst B check

through ID of catalyst tube into mix chamber and out of

the manifold outlet port.

Flush “A” Position

•

Common handle up “Stand-by Position”

•

Solvent flush “A” open

•

“Solvent flush “B” closed

Solvent flows through the solvent flush “A” check into

resin fluid passage. Then through resin A check into the

mix chamber around catalyst tube to manifold outlet

port.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1.

Engage the gun trigger lock, if present.

2.

Turn off the bleed-type master air valve and air to

supply pumps, if present.

3.

Disengage the gun trigger lock, if present.

4.

Hold a metal part of the gun firmly to a grounded

metal waste container. Trigger the gun to relieve

fluid pressure.

5.

Engage the trigger lock, if present.

6.

Open all fluid drain valves in the system, having a

waste container ready to catch the drainage. Leave

the drain valve(s) open until you are ready to spray

again.

7.

If you suspect that pressure has not been fully

relieved after following the steps above, check the

following:

a.

The spray tip may be completely clogged. Very

slowly loosen the air cap retaining ring to relieve

pressure in the cavity between the ball/seat

shutoff and the plugged tip. Clear the tip orifice.

b.

The gun fluid filter or the fluid hose may be com-

pletely clogged. Very slowly loosen the hose

end coupling at the gun and relieve pressure

gradually. Then loosen completely to clear the

obstruction.

c.

After following the steps above, if the spray tip

or hose still seems completely clogged, very

slowly loosen the tip guard retaining nut or hose

end coupling and relieve pressure gradually,

then loosen completely. With tip removed, trig-

ger gun into waste container.

F

IG

. 3 Fluid flow through the manifold

A Side

B Side

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Summary of Contents for M2K 17D763

Page 15: ...Parts 334625B 15 Dimensions ...

Page 16: ...Notes 16 334625B Notes ...