Pressure Control Transducer

26

3A2333B

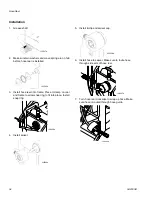

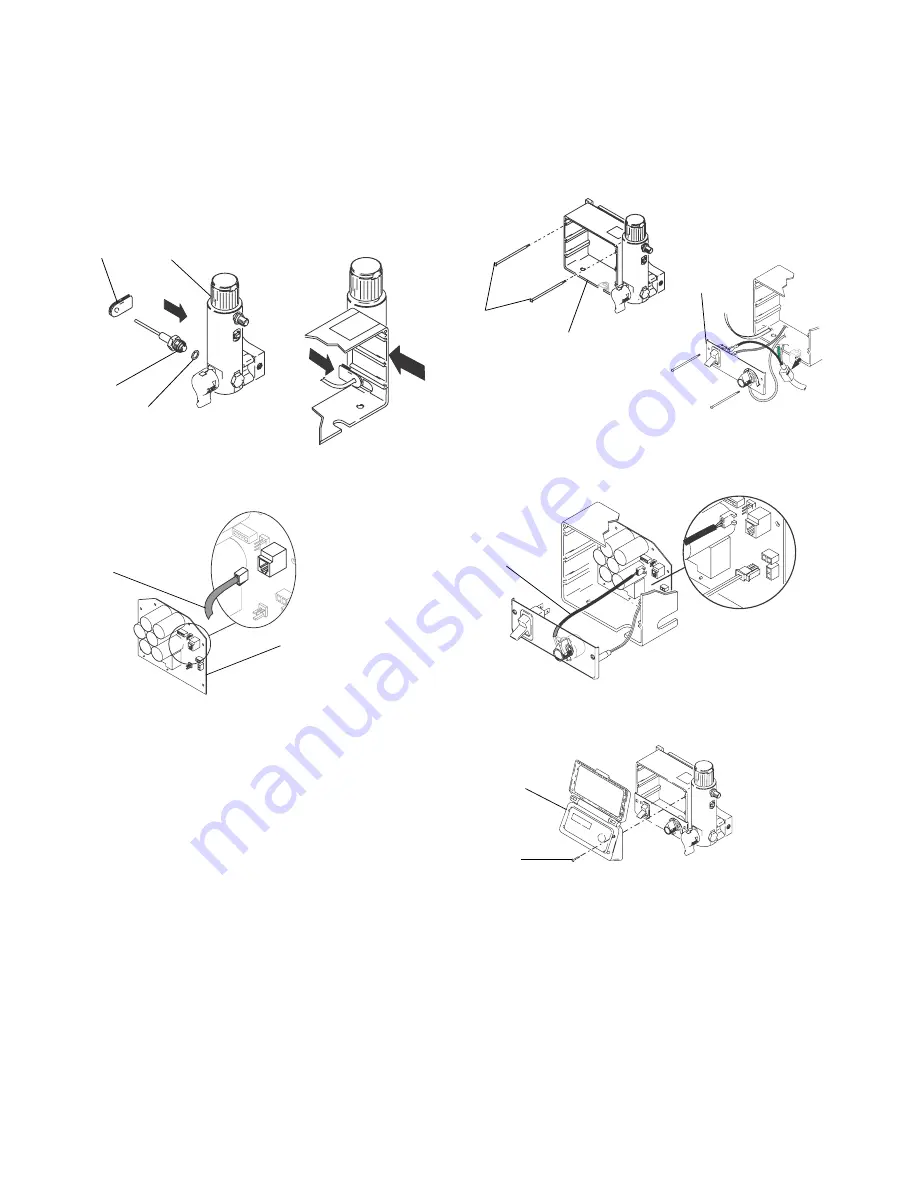

Installation

1. Install o-ring (20) and transducer (86) in filter base

(67). Torque to 35-45 ft-lb (47-61 N•m). Install grom-

met onto transducer (86) and transducer into control

box.

2. Connect transducer connector (E), and Fast Flush

switch connector to control board (95).

3. Install control box (61) and control panel (68) with

four screws (39).

4. Connect potentiometer connector (C), and Fast

Flush switch connector to control board.

5. Install cover (96) with four screws (38).

ti7447a

40

67

20

86

ti13496a

E

95

ti12999a

39

61

ti13494a

68

C

ti13722b

38

96

ti13493b

Summary of Contents for MARK V

Page 38: ...Notes 38 3A2333B Notes ...

Page 39: ...Notes 3A2333B 39 Notes ...