Repair

26

3A0732U

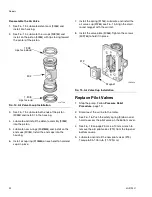

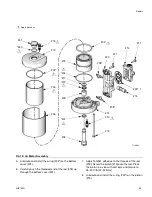

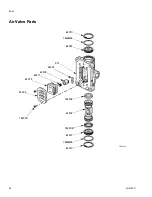

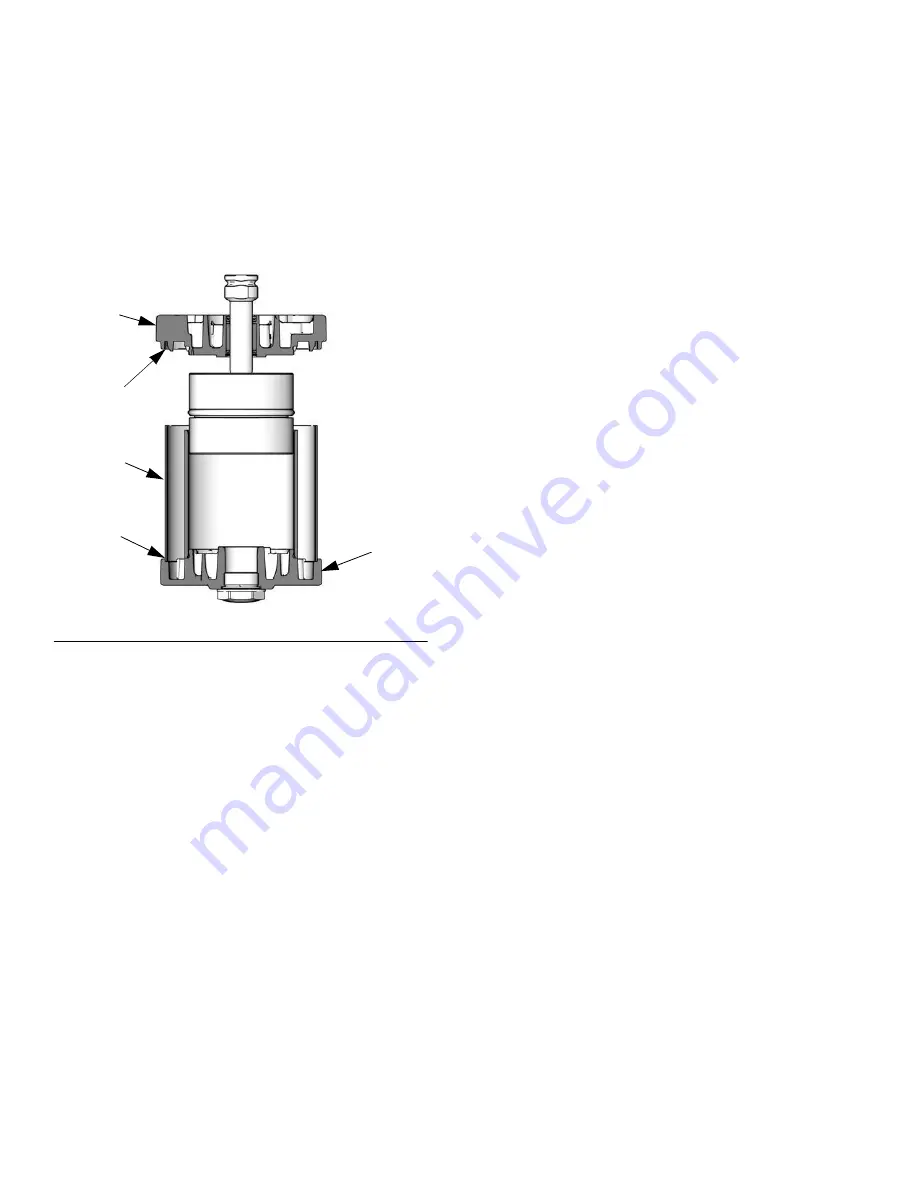

9. See F

IG

. 19. Carefully place the bottom

cover/piston assembly on the cylinder (205), sliding

the piston (219) into the cylinder. The manifold

surfaces of the top and bottom covers must align.

Be sure the shield (206) is in the groove on both the

top and bottom covers.

10. Install the tie bolts (212) hand tight.

11. Install two gaskets (208*) on the manifold (220).

Install the manifold (220). Torque screws (211) to

95-105 in-lb (10.7-11.9 N•m).

NOTE:

The manifold is reversible for ease of placement

of muffler or remote exhaust.

12. Align the air valve gasket (209*

◆

†) on the manifold,

then attach the air valve (214). Torque screws (211)

to 95-105 in-lb (11-12 N•m).

13. Tighten the tie bolts (212) halfway. Work in a

crisscross pattern. Check that the shield (206)

remains in the grooves on both covers. Continue

tightening the bolts in pattern to 11-13 ft-lb (15-18

N•m).

14.

On 3.5 in. motors only,

lubricate the o-ring (230*).

Install it and the plug (231) in the top cover (210).

15. Lubricate and install pilot valves (213) in top and

bottom cover. Torque to 95-105 in-lb (11-12 N•m).

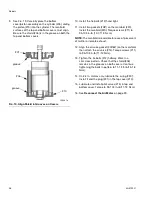

on page 23.

F

IG

. 19. Align Shield in Grooves on Covers

groove

groove

201

206

ti16281a

210