308496 27

Troubleshooting

Voltage Loss Troubleshooting (continued)

7.

To eliminate air gaps in the fluid column, spray

enough fluid to purge the air out between the

voltage isolation system and the spray gun. An air

gap in the fluid hose can break the electrical

continuity between the spray gun and the isolated

fluid supply and cause a low voltage reading on a

voltage meter connected to the isolated fluid

supply.

8.

Check the spray gun cover and barrel for accumu-

lated overspray. Excessive overspray can create a

conductive path back to the grounded gun handle.

Install a new gun cover and clean the exterior of

the gun.

9.

Inspect the entire system for any visible fluid

leakage and repair any fluid leaks that are found.

Pay special attention to the following areas:

Packing area of the spray gun

Fluid hose: check for leakage or any bulges in the

outer jacket, which may indicate an internal leak

Internal voltage isolation system components

Tests

If you still have no voltage, separate the spray gun and

hose from the voltage isolation system and check

whether the gun and hose alone will hold voltage with

the following test.

1.

Flush the system with water and leave the lines

filled with water.

2.

Relieve the pressure and discharge the system

voltage as instructed on page 19.

3.

Disconnect the fluid hose from the voltage isolation

system.

NOTE: Avoid allowing any water to leak out of the fluid

hose as that could cause a significant air gap in the

fluid column up to the gun electrode, which can break

the conductivity path and conceal a potential failure

area.

4.

Position the end of the hose as far as possible

away from any grounded surface. The end of the

hose must be at least 1 ft. (305 mm) from any

ground. Make sure that no one is within 3 ft.

(914 mm) of the end of the hose.

5.

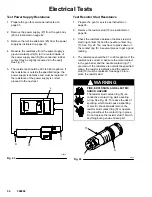

Turn the turbine air to the gun on. Measure the

voltage at the gun electrode with a voltage probe

and meter.

6.

Discharge the system voltage by waiting 30 se-

conds and then touching the gun electrode with a

grounded rod.

7.

If the meter reading is 45 to 55 kV, the gun and

fluid hose are okay, and the problem is in the

voltage isolation system. See the voltage isolation

system manual for further troubleshooting

information.

If the reading is below 45 kV, the problem is in the

gun or fluid hose.

8.

Flush the fluid hose and gun with enough air to dry

out the fluid passages.

9.

Turn the turbine air to the gun on. Measure the

voltage at the gun electrode with a voltage probe

and meter.

10. If the meter reading is 55 to 60 kV, the gun power

supply is okay, and there is probably a dielectric

breakdown somewhere in the fluid hose or gun.

Continue with step 11.

If the reading is below 55 kV, do the electrical tests

on page 33 to check the gun and power supply

resistance. If those tests show the gun and power

supply are okay, continue with step 11, page 28.

Summary of Contents for PRO 5500wb

Page 49: ...308496 49 Notes ...

Page 59: ...308496 59 Notes ...