38 308496

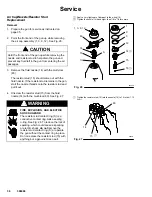

Service

Fluid Packing Rod Removal and Repair

Preventative Maintenance

CAUTION

If the conductive fluid is allowed to leak through the

packings, it will eventually cause an electrical short

through the packings and along the gun barrel,

resulting in a loss of voltage at the tip of the gun.

Severe arcing can cause barrel damage. To avoid

voltage loss and possible barrel damage, preventa-

tive maintenance of the fluid packing assembly must

be performed at regular intervals.

Use the following formula to calculate the best packing

service interval for your application:

Service Interval in Days =

25,000

T x H

Where T = trigger cycles per minute

and

H = hours of operation per day

For example: If the trigger cycles per minute equals

10 and the hours of operation per day equals 8, the

equation would be,

25,000 = 25,000 = 312.5

10 x 8

80

The service interval would be 312 work days.

Procedure

NOTE: The fluid packing rod can be replaced as

individual parts or as an assembly. If the assembly is

purchased, it is pre-adjusted at the factory.

1.

Prepare the gun for service as instructed on

page 35.

2.

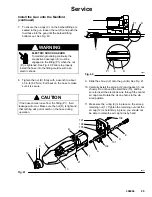

Remove the jam nut (46) and actuator arm (19).

See Fig. 31, page 39.

3.

Remove the air cap assembly, fluid nozzle and

resistor stud and electrode needle as instructed on

pages 36 and 37.

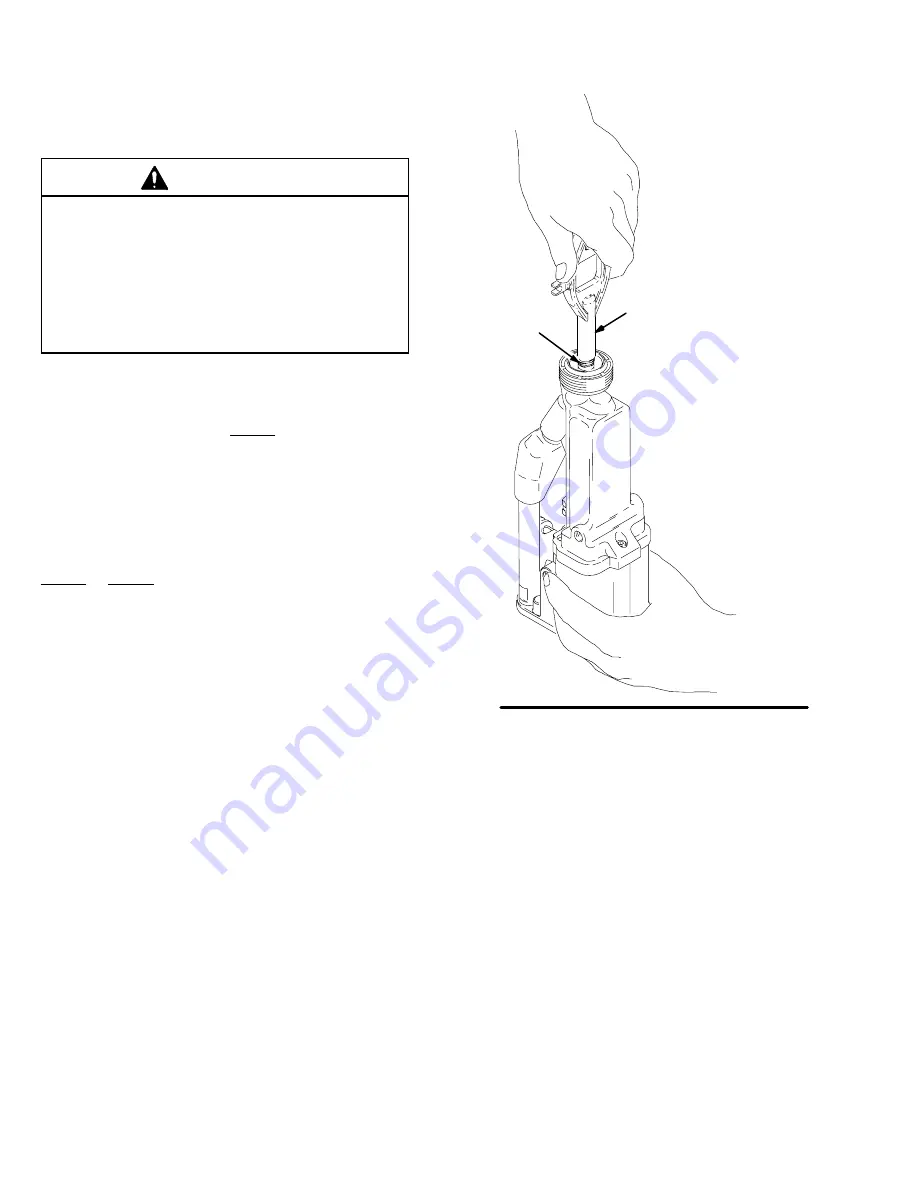

4.

Remove the fluid packing rod assembly (28) with

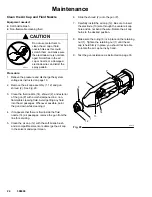

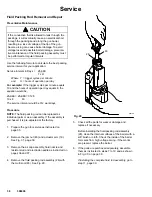

the multi-tool (83). See Fig. 29.

04319A

Fig. 29

83

28

5.

Check all the parts for wear or damage and

replace if necessary.

Before installing the fluid packing rod assembly

(28), clean the internal surfaces of the barrel with a

soft brush or cloth. Check the inside of the barrel

for marks from high voltage arcing. If the marks

are present, replace the barrel.

6.

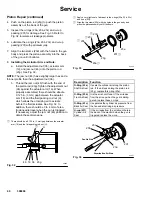

If the parts are purchased separately, assemble

them as instructed in steps 7 to 10 and as shown

in Fig. 30, on page 39.

If installing the complete fluid rod assembly, go to

step 11, page 39.

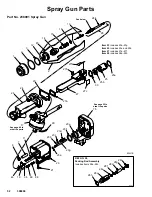

Summary of Contents for PRO 5500wb

Page 49: ...308496 49 Notes ...

Page 59: ...308496 59 Notes ...