SERVICE

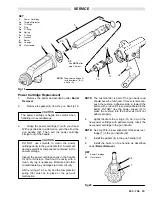

Fluid Needle Replacement

1.

Remove the gun barrel (9) as instructed on page

17. If the power cartridge comes out, carefully press

it back into the handle.

2.

Insert the narrow end of the pressing tool (63c)

through the front of the gun to push the needle back,

then remove the nut (21) and the adjustment nut

(17a). See Fig 17.

3.

Press the needle assembly (17) out the front of

the gun as far as you can with a finger, or by pressing

it against a flat surface. Then use the wrench (63f) to

finish pushing it out. See Fig 16.

4.

Remove the nut (17a) from the new needle

assembly. Then install the new needle assembly

through the front of the gun. Insert the narrow end of

the pressing tool (63c) into the front of the gun and

press to seat the needle. See Fig 17.

5.

Install the new adjustment nut (17a), hex end

first, onto the needle.

6.

Use the pressing tool (63c) to press on the

needle from the front of the gun, then screw the

adjusting nut (17a) all the way to the bottom of the

threads. Remove the pressing tool.

7.

Screw the other nut (21) firmly against the

adjustment nut to lock them together.

8.

Reassemble the gun as described in Barrel

Reassembly.

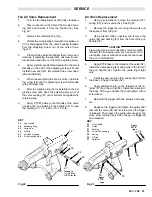

Fig 16

KEY

17

Needle Assembly

17a

Adjustment Nut

21

Nut

63f

Wrench

21

17a

17

63f

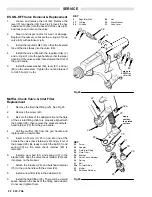

Fig 17

KEY

17a

Adjustment Nut

21

Nut

63c

Pressing Tool

21

17a

63c

Bottom of

thread

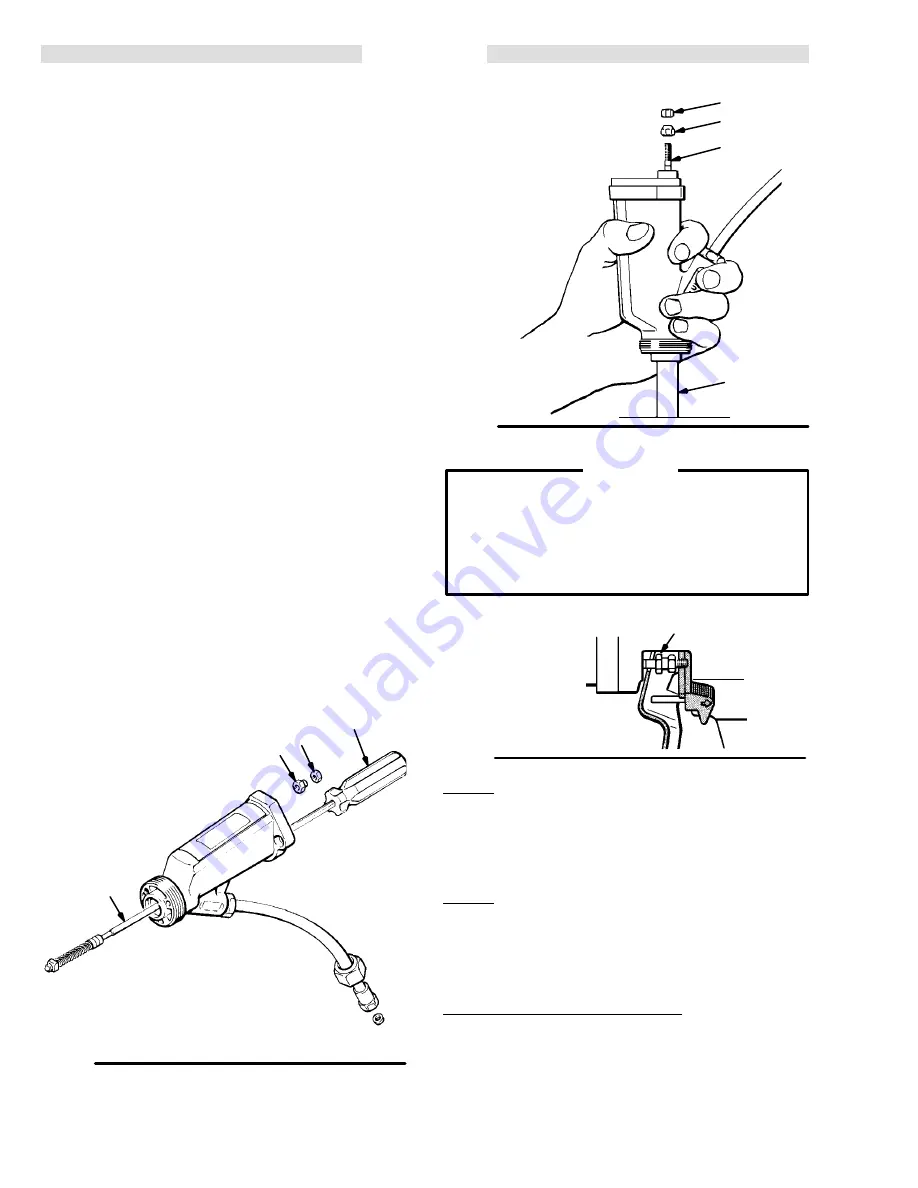

Check the Gun Safety Latch

WARNING

Check to be sure the gun safety latch works prop-

erly each time after you change the needle.

Safety

latch failure or improper use of the safety latch can

result in accidental gun triggering, which could

cause fluid injection or splashing fluid into the eyes

or on skin and result in serious injury.

Fig 18

17a

Trigger MUST NOT

touch nut (17a) when

safety latch is locked.

SPRAY

LOCK

TEST 1

Engage the trigger safety latch to the right, then try to trig-

ger the gun. Look behind the trigger to be sure it is

not

engaging the nut (17a). Then engage the latch to the left

and check again. See Fig 18.

TEST 2

Disengage the trigger safety latch, and trigger the gun

gently to see if you can feel the “lead and lag” operation,

which means the air will come on before the fluid does,

and the fluid shuts off before the air does.

If the gun fails either TEST 1 or 2:

Remove the trigger and the ball seat housing. Back the

nuts

(17a, 21) away from the bottom of the threads.

Reassemble and check Tests 1 and 2 again. Also check

in front of the trigger to make sure the needle still moves.

If the trigger still fails any of these tests now, the needle

assembly (17) is out of tolerance and must be replaced.

Summary of Contents for PRO AA4000

Page 2: ... ...